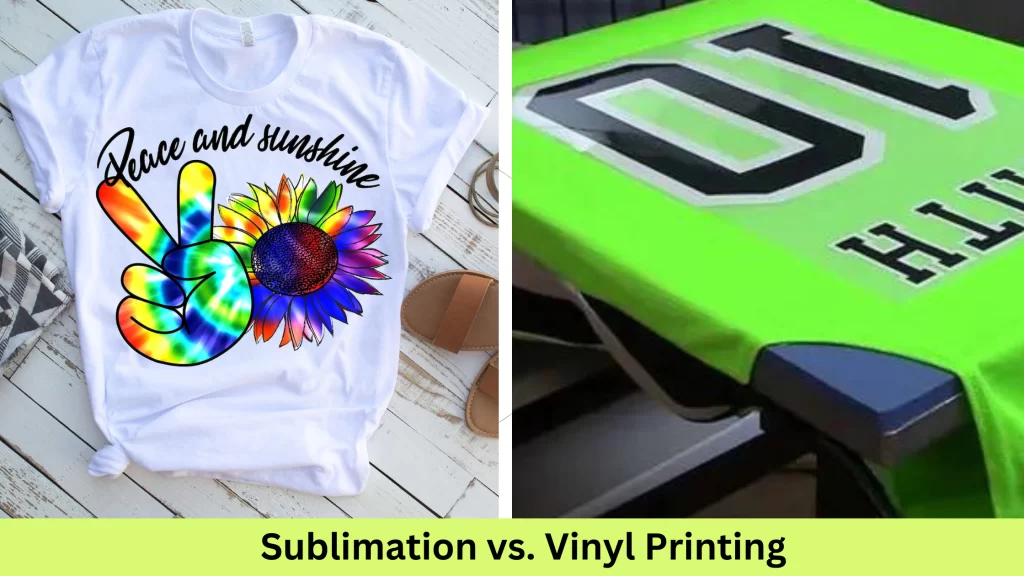

Custom printing has evolved far beyond traditional methods, and sublimation and heat transfer vinyl printing have emerged as two prominent contenders. When it comes to expressing your creativity on various surfaces, be it fabrics, mugs, tumblers, or promotional items, choosing the right printing method makes a huge difference in results.

That’s why I’m here to share my personal experience with two popular printing techniques: sublimation vs. heat transfer vinyl. I’ll share a detailed comparison between these methods and also break down the benefits and drawbacks, helping you discover the perfect fit for your next creative project.

Also read a comparison between sublimation and heat transfer.

Contents

Understanding Sublimation Printing

Sublimation printing is a fantastic technique that allows you to transfer vibrant, long-lasting designs onto various materials. The process works by using heat to turn sublimation ink into a gas, which then penetrates the surface of the material and solidifies, resulting in a permanent print.

What I love about sublimation printing is the incredible range of colors you can achieve. The colors come out sharp and vibrant, with a level of detail that’s hard to beat. Plus, since the ink actually becomes a part of the material, the designs won’t fade or peel off like a sticker or an iron-on patch over time.

Another great aspect of sublimation printing is the limitless color options available. You can bring your wildest design ideas to life without worrying about color limitations. From gradients to complex patterns, the possibilities are endless.

Additionally, sublimation prints are known for their soft and breathable feel. Unlike some other printing methods, the ink doesn’t create a heavy or stiff layer on the material. It retains the fabric’s natural properties, making it comfortable to wear.

However, sublimation printing does have a few limitations. It works best on light-colored polyester and polyester-coated materials, so it may not be suitable for other fabric types like cotton.

Also, it’s important to note that sublimation printing is unsuitable for dark-colored fabrics, as the ink is transparent and won’t appear well on dark backgrounds.

I should also mention that sublimation printing requires a higher initial investment compared to some other printing methods. You’ll need special equipment, such as a heat press and sublimation printer, along with sublimation inks.

Products Perfect for Sublimation Printing

Here is a list of products that are perfect for sublimation printing:

- Polyester apparel (T-shirts, jerseys, hoodies, sportswear)

- Mugs and Drinkware

- Home decor items (pillows, cushion covers, blankets)

- Ceramic tiles and coasters

- Personalized phone cases

- Promotional items and souvenirs (keychains, mousepads, magnets)

- Customized face masks

Understand Heat Transfer Vinyl Printing

Heat transfer vinyl is a popular printing method that allows you to transfer designs onto different surfaces using vinyl material. The process involves cutting the design out of a vinyl sheet and then applying it to the desired substrate.

One of the biggest advantages of heat transfer vinyl printing is its versatility. It works well on a wide range of substrates, including fabrics, glass, metal, and more. This flexibility opens up a world of possibilities for customization.

Unlike sublimation printing, heat transfer vinyl is suitable for both light and dark fabrics. You can create vibrant designs on dark-colored materials using opaque vinyl, which ensures excellent visibility and color vibrancy.

Heat transfer vinyl printing allows for precise and detailed designs with the use of a cutting machine (like Cricut). The cutting process ensures sharp edges and fine details, making it perfect for intricate logos, lettering, or decorative elements. You can achieve a professional and polished look with ease.

Learn the easiest way to sublimate with Cricut machine.

If you are working on small-scale projects, vinyl printing can be cost-effective. You can buy vinyl sheets in various sizes and colors, making it convenient for personalized or limited-run designs. It’s a great option for small businesses or individuals looking to create custom items without breaking the bank.

However, compared to sublimation, heat transfer vinyl offers a more limited color range. While there are various colors available, they may not offer the same level of vibrancy and color depth as sublimation.

Over time, vinyl prints are prone to peeling or cracking, especially with frequent washing or heavy use. It’s important to properly care for vinyl-printed items to ensure longevity.

Additionally, vinyl prints can have a bulkier feel compared to sublimation prints. The vinyl material adds a layer to the surface, which can slightly alter the texture and feel of the fabric or substrate.

Wondering if you can sublimate on vinyl? Yes, you can!

Products Perfect for Heat Transfer Vinyl Printing

Here is a list of products that are perfect for heat transfer vinyl printing:

- T-shirts and apparel (including cotton and dark-colored)

- Hats and caps

- Bags and backpacks

- Decals and stickers

- Banners and signs

- Vehicle graphics

- Window decals

- Personalized gifts (mugs, tumblers, water bottles)

- Sports jerseys and uniforms

- Team merchandise

Comparing Sublimation and Heat Transfer Vinyl Printing

Now let’s dive into a detailed comparison between sublimation and heat transfer vinyl printing, considering various factors that can influence your decision.

a. Print Quality and Durability

When it comes to print quality and durability, sublimation printing stands out with its vibrant colors that truly pop. The ink becomes a part of the material, resulting in excellent color vibrancy and resistance to fading.

For instance, I have a sublimated t-shirt that has retained its bright colors and still looks brand new despite frequent wear and laundering.

On the other hand, heat transfer vinyl printing also provides great color intensity, but it may not have the same level of longevity as sublimation. Over time, vinyl prints can experience peeling or cracking, especially with heavy use or improper care.

However, vinyl printing does offer its own advantages. I’ve used adhesive vinyl to create custom decals for my car, and despite exposure to various weather conditions, the prints have held up well.

If your prints come out dull or faded, here’s a guide to make sublimation brighter.

b. Material Compatibility

When it comes to material compatibility, sublimation printing is primarily suitable for polyester or polyester-coated substrates (fabric, ceramic mugs, metal tumblers, etc.).

This method seamlessly integrates with fabrics like athletic performance wear, providing breathability and moisture-wicking properties. However, it performs poorly on other fabric types like cotton or natural fibers.

Heat transfer vinyl, on the other hand, is a more versatile printing method in terms of material compatibility. It can be applied to various surfaces such as fabrics (including cotton and blends), glass, metal, and even walls.

c. Design Flexibility and Customization

Sublimation printing allows for stunning color gradients and photographic prints. This is ideal for reproducing detailed artwork on different mediums or creating personalized photo gifts.

Heat transfer vinyl printing, on the other hand, excels in precise layering and multi-color designs. I’ve used vinyl to create intricate logos on a company’s promotional items and personalized text, adding a pop of color to various surfaces.

d. Production Speed and Efficiency

Sublimation printing requires more setup time due to the preparation of sublimation transfers and the use of a heat press.

Heat transfer vinyl generally has a quicker setup and printing time compared to sublimation, and it is faster for smaller orders or individual items.

If I speak the truth, sublimation printing shines when handling larger or more complex orders. With sublimation, you can print multiple items simultaneously, making it ideal for bulk production.

e. Cost Considerations

Sublimation printing requires a higher initial investment, including specialized equipment such as a heat press and sublimation printer, along with compatible inks and sublimation papers. However, once you have the setup, the production costs for sublimation are relatively lower, especially for larger quantities.

Heat transfer vinyl printing has a lower initial investment, particularly for small-scale projects, but can become more expensive for more significant quantities due to material and labor costs.

Choosing the Best Method for Different Applications

The choice between sublimation and heat transfer vinyl printing depends on the specific applications and printing requirements of your business. Here are a few examples to guide you:

1. Apparel and Fashion Industry

In the apparel and fashion industry, both sublimation and heat transfer vinyl printing have their place. When it comes to performance wear and sportswear, and customized t-shirts, sublimation printing is often the go-to choice because it offers vibrant colors and breathability.

On the other hand, vinyl printing is suitable for a range of garments, including light and dark fabrics, and is often used for bold designs and precise detailing.

Screen printing is also a great way to print vibrant designs on garments. Read a detailed comparison between sublimation and screen printing.

2. Home Decor and Accessories

Both sublimation and heat transfer vinyl printing can bring a personalized touch to your living space. Both can be used for customized pillows, cushions, mugs, and drinkware.

I prefer sublimation over vinyl heat transfer for personalization as it provides brighter results with more color options.

And the best part is, colors are ever-lasting, so no matter how many times you wash your cushions and pillow covers, they’ll always look new after a wash.

3. Promotional Products and Branding

Heat transfer vinyl printing is popular for logo printing on giveaways, creating a professional and memorable impression, such as pens, keychains, business card holders, etc. The ability to create sharp and detailed logos makes vinyl a great choice for branding items.

Sublimation printing, on the other hand, can be used to create customized corporate gifts with vibrant colors and high-quality prints.

I’ve used sublimation to create personalized notebooks and desk accessories for client gifts, and they’ve been well-received.

4. Fine Art and Photography

Sublimation printing is often preferred for reproducing artwork on various mediums, such as canvas and metal prints, creating unique and visually stunning pieces. It allows for accurate color reproduction and high-resolution details.

I am not really a fan of the heat transfer vinyl printing method to print and reproduce photos because it is not always 100% accurate.

Conclusion

The comparison between sublimation vs. heat transfer vinyl printing has shed light on the strengths and limitations of each method.

Sublimation printing stands out in delivering vibrant and long-lasting prints on light-colored polyester fabrics, making it a go-to choice for apparel, home decor, and personalized items.

Whereas, heat transfer vinyl offers versatility on various substrates, including dark-colored fabrics, glass, and metal. It allows for precise designs, making it ideal for personalized items, promotional products, and branding purposes.

Consider the nature of your business, desired outcomes, and long-term goals to choose the right method for your printing needs.

Frequently Asked Questions

What lasts longer, vinyl or sublimation?

Sublimation prints tend to last longer than vinyl prints due to their fade-resistant colors and durability.

What are the disadvantages of sublimation?

Sublimation is limited to polyester and polyester-coated substrates, is not suitable for dark-colored or cotton fabrics, and requires a higher initial investment in specialized equipment and inks.

What is the difference between Cricut sublimation and vinyl?

Cricut sublimation involves heat transferring ink onto polyester or polyester-coated materials, while vinyl printing uses adhesive vinyl cutouts to transfer designs onto various surfaces using heat or pressure.

What’s better than sublimation?

The choice of printing method depends on the project requirements. Other methods like heat transfer vinyl (HTV) or screen printing may be better for specific applications, such as precise designs on different materials.

How does the color vibrancy compare between sublimation and vinyl printing?

Sublimation printing offers exceptional color vibrancy and saturation. The ink used in sublimation becomes a part of the fabric or substrate, resulting in vibrant and long-lasting colors.

On the other hand, vinyl printing provides good color intensity, but it may not match the same level of vibrancy as sublimation. Vinyl prints can appear slightly thicker and may have a glossier finish, which can affect the overall visual impact of the colors.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023