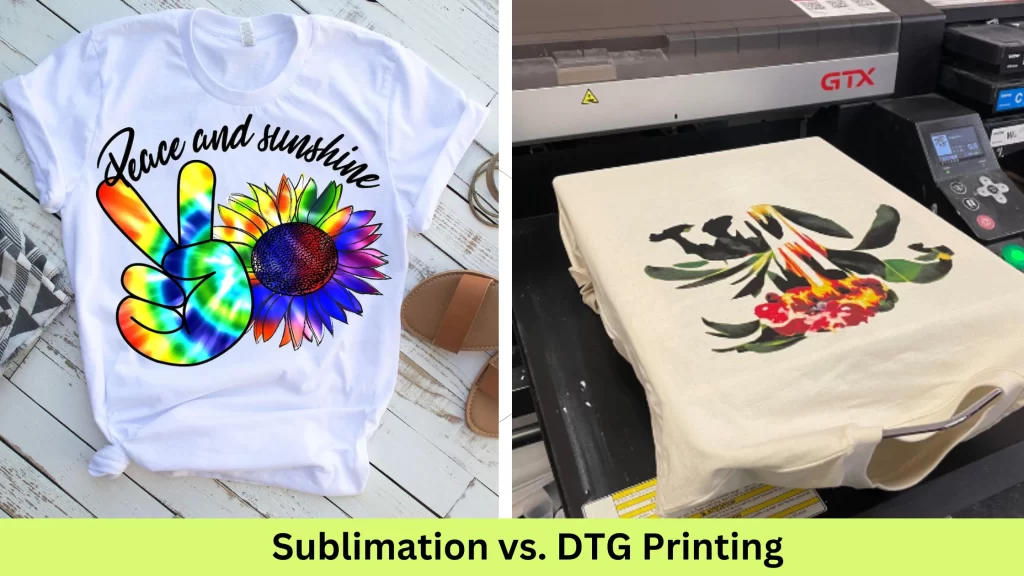

DTG and sublimation are two of the most popular printing methods to print bright designs on garments. These techniques have the potential to deliver stunningly vibrant results, but each method has its own strengths and limitations. You need to know the key differences between the two methods before choosing the right one for your needs.

In my experience, DTG printing produces brighter results than sublimation printing. This is because the ink is applied directly to the garment, and it is not diluted by the fabric. However, sublimation prints are more durable than DTG.

Now, let’s dive deeper into the world of DTG vs. sublimation printing and uncover the secrets to vivid and remarkable prints.

Also, read about DTF vs. Sublimation printing.

Contents

Understanding DTG Printing

DTG (Direct-to-Garment) printing is a modern technique that involves printing designs directly onto the fabric using a specialized printer. The printer operates similarly to an inkjet printer, but instead of paper, it prints directly onto the garment’s surface. The ink is absorbed into the fabric fibers, creating a vibrant and long-lasting print.

Unlike traditional methods that require screens or transfers, DTG allows for the seamless integration of intricate designs and gradients onto garments.

Advantages of DTG Printing

One of the significant advantages of DTG printing, especially when it comes to achieving bright results, is its ability to reproduce colors with exceptional precision. The level of detail and color accuracy that DTG can achieve is truly impressive. Whether it’s capturing subtle shades or vibrant hues, DTG excels at reproducing the full spectrum of colors, making your designs come to life.

Additionally, DTG is well-suited for printing complex designs and gradients. The printer’s advanced technology allows for smooth transitions between colors, enabling the creation of visually stunning prints. This makes it an ideal choice for designs with photo-realistic artwork, where capturing every detail is crucial.

When it comes to printing on dark garments, DTG has a significant advantage – the use of white ink. By incorporating a white ink layer as a base, DTG printing ensures that colors appear vibrant and vivid even on dark fabrics. This opens up a world of possibilities for creating eye-catching designs on a variety of garments, regardless of their color.

Disadvantages of DTG Printing

As with any printing method, DTG has some limitations. Some fabric types require pre-treatment before DTG printing to ensure optimal adhesion of the ink. This additional step adds complexity and time to the printing process.

In terms of cost, DTG printing can be relatively expensive for large-scale production due to the high costs associated with equipment and ink. While it’s perfect for small batches, it may not be as cost-effective for mass production.

Additionally, over time, there is a potential for color bleeding or fading. This is because the ink is applied directly to the garment, and it is not protected by a layer of fabric, or anything else.

Understanding Sublimation in Garments Printing

Sublimation printing is a process of transferring images or designs from a special paper to a substrate using heat and pressure. The ink is turned into a gas and then re-solidifies on the substrate.

Since we are talking about printing on garments, the process starts with printing the design onto a special sublimation paper using sublimation inks. The printed design is then placed in direct contact with the polyester fabric and subjected to heat and pressure. Under these conditions, the ink vaporizes and penetrates the fabric, creating a permanent bond. The result is a print that becomes part of the fabric itself, ensuring long-lasting and vibrant colors.

Good Things about Sublimation Printing

One of the significant advantages of sublimation printing, especially for achieving bright results, is the vibrancy and longevity of the colors. Sublimation inks have excellent color saturation, allowing for eye-catching prints. These colors do not fade easily, even after repeated washings, ensuring that your designs remain vivid and appealing.

Another advantage is its ability to seamlessly print all-over designs. Whether you are looking to cover an entire garment or create a continuous pattern, sublimation printing can achieve this effortlessly.

Sublimation printing is particularly well-suited for polyester fabrics. Polyester has a molecular structure that readily accepts the sublimation ink, resulting in vibrant and high-quality prints. This makes sublimation an ideal choice for sports jerseys, active-wear, and other polyester-based garments, where durability and color intensity are paramount.

Not So Good Things about Sublimation Printing

Dark garments pose a challenge since sublimation inks are transparent. As a result, vibrant colors may not appear as intense on dark fabrics compared to light-colored or white fabrics.

Speaking from my personal experience, I’ve noticed that sublimation works best on light-colored polyester shirts.

Another limitation of sublimation printing is the complexity involved in printing on non-polyester fabrics. Sublimation inks require a polyester base to bond effectively, so printing on fabrics with low polyester content may yield unsatisfactory results.

Lastly, sublimation printing requires an initial investment in specialized equipment, including a sublimation printer, heat press, and sublimation inks. While the quality and versatility of sublimation printing make it a worthwhile investment, the upfront costs can be a little higher.

Comparing DTG and Sublimation Printing for Bright Results

As someone who has extensive hands-on experience with both DTG and sublimation printing, I am excited to compare each method to achieve bright and visually stunning prints.

Let’s explore the key factors that differentiate these two methods and their impact on the final results.

Print Quality

DTG printing typically produces better detail and color accuracy than sublimation printing. This is because the ink is applied directly to the garment, rather than being transferred from a paper.

Dye sublimation printing can produce brighter and more vibrant colors than DTG printing. This is because the ink is actually embedded into the fabric, rather than simply sitting on top of it.

Fabric Compatibility

When deciding between DTG and sublimation printing, it’s crucial to consider the fabric type. DTG printing offers versatility, allowing for printing on a wide range of fabric types, including cotton, blends, and synthetic materials.

On the other hand, sublimation printing is most suitable for polyester or polyester-coated substrates, as the dyes bond exceptionally well with these fabrics.

Design Complexity

Design complexity is another crucial aspect to consider. DTG printing is well-equipped to handle intricate and detailed designs with ease. Whether it’s fine lines, small text, or intricate patterns, DTG can accurately reproduce these elements.

Sublimation printing also handles complex designs effectively, especially when it comes to gradients, shading, and all-over patterns, but results may not be as good as DTG.

Cost Analysis

When I purchased the supplies for DTG printing, I found that the costs can vary depending on various factors. The DTG printer itself is a significant investment, with prices ranging from $2,000 to $10,000, depending on the brand and model.

Additionally, the pretreatment solution, which is essential for ensuring optimal ink adhesion, typically costs around $70 to $100 per gallon, depending on the brand and quantity.

As for the DTG inks, they usually come in cartridges or bottles and can cost anywhere from $50 to $150 per color, depending on the brand and volume.

Since I have mentioned my love for sublimation printing in my other posts, I can provide insights into the associated costs. The main investment for sublimation printing lies in a sublimation printer, capable of handling large-format prints, which can range from $500 to $3,000 or more, depending on the brand and features.

In addition to the printer, you will need sublimation inks, that can vary depending on the brand, color range, and quantity, but you can expect to spend around $50 to $100 per cartridge. The rest of the equipment like sublimation paper, protective sheet, and heat-resistant tapes do not cost much.

Factors to Consider When Choosing Between DTG and Sublimation Printing

When deciding between DTG and sublimation printing, several key factors should be taken into account to ensure you make an informed choice. Let’s explore these factors in detail:

Print Volume and Production Requirements

Consider the volume of prints you need and your production requirements. DTG printing is suitable for on-demand and small-batch production, making it ideal for personalized or customized items.

Sublimation printing, on the other hand, is more efficient for larger quantities due to its ability to produce multiple prints simultaneously.

Fabric Types and Intended Use of the Printed Items

The fabric type and intended use of the printed items play a significant role in the decision-making process. DTG printing works well on various fabric types, including cotton and blends, providing versatility in printing on different materials.

Sublimation printing, on the other hand, is specifically designed for polyester fabrics. If you primarily work with polyester-based materials or require excellent durability, sublimation printing may be the better choice.

Budget Constraints and Cost-Effectiveness

Evaluate your budget constraints and consider the cost-effectiveness of each printing method. DTG printers generally have a higher upfront cost compared to sublimation printers, and they can be more expensive in terms of ink and maintenance costs.

Sublimation printers require an initial investment but offer a cost-effective approach for larger production runs due to lower ink costs.

Design Complexity and Customization Options

Assess the complexity of your designs and the level of customization you require. DTG printing is well-suited for intricate and detailed designs, including gradients, shading, and bold text. It offers the flexibility to print complex artwork with precision.

On the other hand, sublimation printing, with its ability to seamlessly print all-over designs, is better suited for patterns, gradients, and continuous designs.

DTG vs. Sublimation vs. Screen Printing

Having worked extensively with DTG, sublimation, and screen printing throughout my career, I’ve gained valuable insights into the unique qualities and considerations of each method. Here’s my personal perspective on these popular printing techniques.

When it comes to DTG printing, I appreciate its versatility and ability to produce quality prints with exceptional detail. The direct-to-garment process allows for accurate colors, making it suitable for intricate designs and personalized customization.

The ability to print on various fabric types, including cotton and synthetics, offers flexibility and opens up a wide range of possibilities.

On the other hand, sublimation printing has its own distinct advantages. The ability to infuse dyes into polyester fibers creates prints with unmatched vibrancy and longevity. It truly shines when it comes to all-over designs, as the process seamlessly covers the entire garment, delivering visually captivating results.

However, sublimation printing is primarily limited to polyester or polyester-coated substrates, which can impact the range of materials available for printing.

Lastly, there’s screen printing – a traditional method that still holds its own. Screen printing offers exceptional durability and the ability to achieve vibrant colors, especially on dark fabrics. It’s a cost-effective option for large production runs, making it popular in the apparel industry.

However, screen printing can be less suitable for complex designs and printing tiny details. Screen printing is also not suitable for small-batch orders due to the setup and preparation involved.

Here’s a detailed comparison between sublimation vs screen printing.

Conclusion: So which is Better?

So, when deciding between DTG and sublimation printing, it’s important to carefully consider your specific needs and priorities. Both DTG and sublimation printing have their strengths when it comes to achieving bright results.

DTG printing offers versatility and precision, while sublimation printing delivers vibrant colors on light-colored polyester fabrics. Choosing between them depends on your specific needs and preferences.

Consider factors such as print volume, fabric types, budget, and design complexity to make the best choice for your desired outcomes.

Frequently Asked Questions

Is DTG better than sublimation for durability?

Sublimation printing tends to have better durability on polyester fabrics, as the ink becomes part of the fabric, resulting in long-lasting prints.

What is the main difference between DTG and sublimation printing processes?

DTG (Direct-to-Garment) printing involves using specialized inkjet printers to directly print designs onto garments. The ink is absorbed into the fabric, resulting in vibrant and detailed prints.

On the other hand, sublimation printing uses heat and pressure to transfer dye onto polyester or polyester-coated substrates. The dyes convert into a gas and penetrate the fabric, creating long-lasting and vivid prints.

Which method offers better color accuracy and vibrancy, DTG or sublimation printing?

Both DTG and sublimation printing can achieve excellent color accuracy and vibrancy. However, sublimation printing often offers superior color reproduction due to the dye penetration into the fabric fibers. This results in prints with exceptional brightness and longevity.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023