Have you ever seen those colorful, abstract designs on t-shirts, mugs, and phone cases and wondered how they are made? Well, the process is called sublimation printing, and it’s a type of dye heat transfer. Here, we’ll take a look at what is sublimation printing and its incredible potential.

Contents

What is Sublimation Printing?

Sublimation is a process that turns a solid into a gas without going through a liquid state. In the context of printing, sublimation printing involves printing a design onto a sublimation paper, and then transferring it on a substrate using heat and pressure. These substrates include t-shirts, mugs, hats, hoodies, tumblers, and many more.

I have personally used this printing technique to create custom shirts for my family and friends. It’s a very easy and affordable way to create personalized gifts. If you are looking for a way to create custom apparel or home goods, sublimation printing is a great option.

The beauty of sublimation printing lies in its ability to produce complex, full-color designs with exceptional detail and color gradients. It is particularly well-suited for polyester fabrics and specially coated materials, as they have a higher affinity for sublimation ink.

This technique enables the creation of custom apparel with vibrant, durable prints that seamlessly blend into the fabric. The breathable nature of sublimated shirts ensures comfort even after countless washes, making them a popular choice for sports teams, fashion brands, and personalized merchandise.

Sublimation Printing Process

Sublimation printing is an excellent method that can be used to present your business logo or specified graphics on your product.

Lately, this method has become very popular among aspiring graphic designers. You can print high-quality pictures that do not smudge or crack easily. Let’s explore the sublimation process in detail:

What You’ll Need

There are a few things that you’ll need to get started with your sublimation printing project;

- A sublimation printer

- Sublimation ink

- Sublimation transfer paper

- Heat press machine

- Substrate (the item you want to transfer the image to)

Read a detailed article on what is sublimation ink and its uses.

How Does It Work?

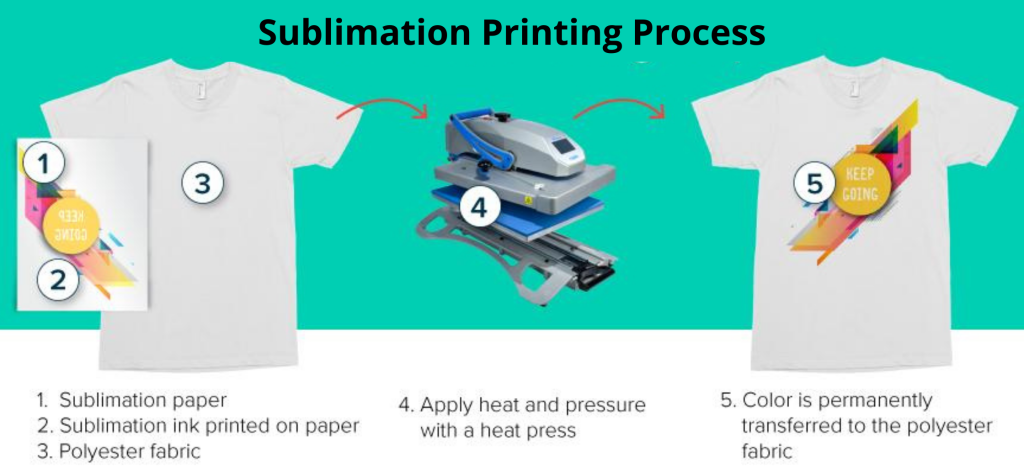

The image is first designed using sublimation design software and then printed onto a sheet of sublimation paper using sublimation ink. After that, cut the design according to the substrate and place it on the substrate you want to transfer the image.

Once the paper is aligned on the substrate where you want to print it, apply heat and pressure using a heat press machine – it’ll cause the dyes to “sublimate”, which means turn into gas.

This gas then penetrates into the surface of the substrate (fabric, ceramic, polyester, etc.) and bonds to permanently transfer the image. It results in bright, vibrant colors that are resistant to fading.

Benefits of Sublimation Printing

Customizing and personalizing products such as cups, t-shirts, glass, tumblers, phone cases, tiles, and apparel have quickly become a popular and profitable industry. Sublimation is an easy and cost-effective process to add personalization to the products.

The sublimation printing method has many benefits. It’s an eco-friendly process because there is no waste produced unlike traditional screen printing products, and it’s also a fast and efficient process.

This technique allows intricate details to show up in an image and can be used on a variety of different products. It can be used on any porous material which makes it an excellent process for fabric printing, ceramic mugs, phone cases and so much more. It’s also cost-effective and low in price. You can get a mug printed with your logo for just a couple of dollars.

Finally, the sublimation prints are long-lasting and offer a high-quality print look. The image will not fade and the colors won’t bleed so you can get a colorful, bright design.

Designs for Sublimation Printing

I have been using sublimation printing for a few years now, and I have found that the best designs for sublimation printing are those that are simple and easy to read. I have had good results with solid colors, high-contrast designs, and vector graphics.

I have also had good results with photographs, but it is important to use high-quality images that are in CMYK format.

Note that images with gradients, text, or fine details can be difficult to sublimate and may not look as good as other types of designs.

Designs That Work Well with Sublimation Printing

Solid colors: Solid and vibrant colors work well with sublimation printing because they can be printed clearly and accurately.

High-contrast designs: High-contrast designs with exceptional vibrancy and sharpness, such as those with black and white or bright colors, also work well with sublimation printing.

Vector graphics: Graphics that are made up of lines and shapes, work well with sublimation printing because they can be scaled to any size without losing quality.

Photographs: Photographs can also be sublimated, but they must be high-quality images in CMYK format.

Designs That Don’t Work Well with Sublimation

Images with gradients: Images with gradients, such as those with a gradual change from one color to another, do not work well with sublimation printing because the gradients can be distorted when the image is printed.

Images with fine details: Images with fine details, such as those with complex patterns or small text, may not be visible when they are sublimated.

If you are new to sublimation printing, I recommend starting with simple designs and working your way up to more complex designs as you gain experience.

Is There White Ink in Sublimation Printing?

No, there is no white ink in sublimation printing. And the common concept is that the white color cannot be sublimated. However, there are a few ways to create white images with sublimation printing when printing on darker materials.

It’s true that the absence of white ink can affect the appearance of the design. White areas in the design will appear transparent, allowing the color of the fabric to show through. This can result in a different color outcome than what may be expected.

To achieve white or light colors in sublimation printing on darker materials, alternative techniques like layering a white base or using pre-coated substrates that contain a white layer can be employed. These methods help to provide a base for the colors to appear more vibrant and accurate.

Learn how to sublimate on black shirts.

Wrapping Up

Sublimation printing is an excellent process that can help you create a wide range of products. From custom shirts to corporate giveaways, sublimation printing is a great way to increase your brand exposure and even generate some revenue.

If you are looking for a unique way to add some color and customization to your products, look no further than dye heat transfer. The dye sublimation printing process is a great example of how the world is becoming more digitalized with technology, allowing us to have full-color designs on our favorite clothes, mugs or phone cases!

Frequently Asked Questions

What does sublimation printing do?

The sublimation printing process is a dye print heat transfer process. The printer will print directly onto specially made heat transfer paper which can then be transferred onto almost any material. Sublimation printing is great for businesses that are looking to have custom prints in large quantities. It’s also perfect for making personalized gifts for someone special!

Can a regular printer be used for sublimation?

No, a regular printer cannot be used for sublimation. A sublimation printer prints onto heat transfer paper that a regular printer is not capable of.

Is sublimation printing permanent?

Yes, sublimation printing is permanent and can be used on fabric. It is a permanent transfer that will not peel or fade with time.

Which is better sublimation or heat transfer?

This question doesn’t really have a straight answer. For businesses that need to print in bulk, sublimation is great because it can produce high-quality prints quickly and efficiently. For those looking for more specialty or designer pieces, heat transfer printing is a great option as the images will be able to fade over time. This gives a more vintage or unique look that many people love!

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023