Sublimation paper and heat transfer paper are two popular options for creating customized t-shirts, hoodies, and other garments. But what’s the difference between both and which one is better for fabric decoration?

Both are great techniques, but the choice will depend on your personal needs. To make an informed decision, let’s explore and understand both types of papers to find the suitable one for your garments printing projects.

Read a detailed comparison between sublimation and heat transfer printing methods.

Contents

Sublimation Paper and How It Works

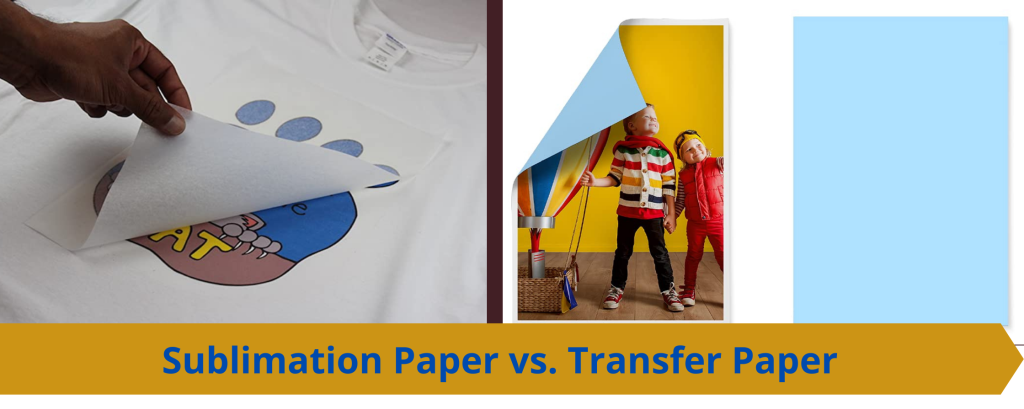

Sublimation paper is a special type of paper that is used to transfer images to fabric, ceramic mugs, metal tumblers, wood ornaments, and other materials. The process of sublimation is what makes this possible.

Sublimation paper is coated with a special polymer that allows the ink to sublimate (changes from a solid to a gas). The polymer also helps to prevent the ink from bleeding or smearing.

It is commonly used for printing on polyester fabrics, as well as items with a polymer coating, such as mugs, phone cases, mouse pads, ceramic tiles, etc. However, it produces bright results only on white substrates and does not work well on dark-colored substrates.

The Sublimation paper is widely used in the textile industry for creating personalized apparel, sportswear, customized garments, and fashion apparel.

Additionally, sublimation paper is popular in the promotional products industry for producing customized gifts and promotional items. Its ability to reproduce complicated designs, vibrant colors, and photographic images makes it a favored choice for a range of projects.

To use sublimation paper, you will need a sublimation printer, sublimation ink, and a heat press. The printer will print the image onto the sublimation paper, and the heat press will transfer the image to the garments or other items using heat and pressure.

Top Sublimation Paper Brands

- Printers Jack

- A-SUB

- Ink Experts

- HTVRONT

Heat Transfer Paper and How It Works

Heat transfer paper is mainly used to transfer images to different types of fabric using the heat transfer process.

In heat transfer, the ink is heated to a very high temperature, which causes it to melt and then solidify to create a layer on the surface of the material.

Heat transfer paper is very smooth and also coated with a special polymer (just like sublimation paper), that helps to prevent the ink from bleeding or smudging.

One of its primary advantages is its versatility. Heat transfer paper works effectively on a wide range of fabrics, including cotton, blends, and polyester. This makes it an excellent choice for creating personalized t-shirts, tote bags, hoodies, and other fabric-based items.

Best of all, transfer paper can be used in any inkjet printer for printing colorful designs. And these papers are a lot easier to use than sublimation paper, and it is less likely to produce mistakes.

Read if you can use sublimation ink on heat transfer paper.

The process of printing with heat transfer paper is relatively straightforward and doesn’t require specialized equipment or extensive training. With a standard inkjet printer, you can easily print your designs onto the transfer paper and transfer them onto the desired garment using a heat press or even a regular household iron (but a heat press machine is better for vibrant results).

Top Heat Transfer Paper Brands

- TransOurDream

- SNAP

- PPD

- A-SUB

Differences between Sublimation Paper and Heat Transfer Paper

The main difference is that sublimation paper can be used to transfer images onto polyester fabrics or polymer-coated items, while heat transfer paper can be used on a variety of fabrics, including cotton, polyester, and blends.

Sublimation paper can only be used on light-colored fabrics, as the dark colors will not end up printing accurately. Heat transfer paper can be used on both light and dark-colored fabrics.

In addition, sublimation paper creates permanent prints, while heat transfer paper creates a layer on the surface of the substrate, which is durable but not permanent.

Let me tell you a little story about my own experiences with these two methods.

I started out with sublimation paper, because I heard it was the best way to get high-quality transfers. And it was true, the transfers I made with the sublimation paper were amazing. But there was one problem: I could only use them on light-colored fabrics.

I wanted to make transfers on dark fabrics, too, so I switched to heat transfer paper. And guess what? The transfers I made with heat transfer paper were still pretty good! They weren’t as high-quality as the sublimation transfers, but they were still good enough for me.

So, if you want the highest possible quality transfer, then a sublimation paper is the way to go. But if you need to be able to use dark fabrics, then heat transfer paper is a good option.

Of course, you could always use both methods. I know a few people who do that, and they’re able to get the best of both methods.

1. Substrate Type

When it comes to substrate and fabric type, sublimation paper is primarily suitable for polyester fabrics and items with a polymer coating.

On the other hand, heat transfer paper is versatile and can be used on a variety of fabrics, including cotton, blends, linen, and even polyester.

2. Garment Colors

Sublimation printing works best on light-colored or white garments. Since the ink is transparent, it blends with the fabric, resulting in vibrant colors. Read what color shirts can you sublimate on.

Heat transfer paper allows for printing on both light and dark-colored garments. Dark-colored heat transfer paper is designed with a white background to ensure that the colors stand out on darker fabrics.

3. Durability and Feel

Sublimation prints become a part of the substrate and they do not feel as an extra layer on top. That’s why sublimation paper takes the lead when it comes to durability.

Prints created with sublimation paper have exceptional longevity and strength. They are resistant to fading, cracking, and peeling, ensuring that your designs stay vibrant and intact even after multiple washes.

On the other hand, prints created using heat transfer paper are not durable enough to withstand the harshness of temperature. The heat transfer paper creates an additional layer of ink on top of the surface that you can feel by touch, and it might crack or fad after a few washes.

4. Vibrancy

Well, most people say that both sublimation paper and heat transfer paper can produce vibrant colors. But I’ve found sublimation papers offering a wider color range and can reproduce more vivid and detailed images.

Perhaps this is because of the special sublimation ink or the CMYK colors.

Also, read about DTF vs. Sublimation printing.

5. Weeding Process

The weeding process, which involves cutting excess paper from designs, differs between the two papers.

Heat transfer paper typically requires manual weeding or cutting, where you need to carefully peel off the unwanted portions of the design. There are some laser-cut auto-weeding heat press machines available on the market, but they are costly!

On the other hand, sublimation paper does not require weeding as the ink becomes a permanent part of the fabric or substrate during the sublimation process.

6. Cost of the Set-up

Sublimation paper may have higher initial costs due to the specialized equipment required, such as a sublimation printer, sublimation ink, and a heat press. However, sublimation printing can be more cost-effective in the long run, especially for larger-scale production, as it offers lower per-unit printing costs.

Heat transfer paper, on the other hand, has lower upfront and operational costs as it can be used with a regular inkjet printer.

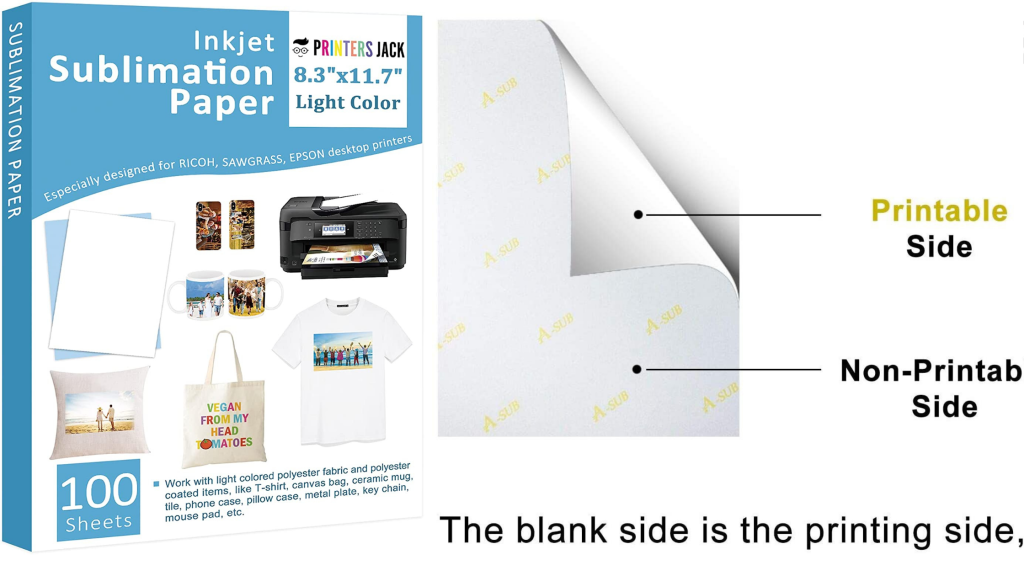

Comparison Table: Sublimation Paper vs. Heat Transfer Paper

| Feature | Sublimation Paper | Heat Transfer Paper |

| Process | Sublimation | Heat transfer |

| Printer compatibility | Sublimation printer | Inkjet or laser printer |

| Ink | Solid | Liquid |

| Transfer | Gas | Solid |

| Image Quality | Very high | High |

| Durability | Long-lasting | Durable |

| Color Vibrancy | Excellent | Good |

| Weeding Process | Easy | Difficult |

| Cost-Effectiveness | Expensive startup cost | Less expensive |

Final Words

In conclusion, sublimation paper produces a longer-lasting, smoother, and glossier image than heat transfer paper. However, it is a lot easier to use transfer paper on a wider range of fabrics.

So, the choice between sublimation paper and heat transfer paper ultimately depends on your specific printing needs and preferences. If you are looking for an easy and mistake-free process, then transfer paper is the right choice.

However, a sublimation paper is the better option if you are looking for a permanent print that will not fade or peel over time.

Frequently Asked Questions

Is transfer paper the same as sublimation paper?

No, transfer paper and sublimation paper are two different types of paper that are used for transferring images on substrates. Sublimation paper is used to print using a sublimation printer and special sublimation ink. However, the transfer paper can be used in any inkjet printer to print beautiful images.

Can you use sublimation paper in any printer?

No, sublimation paper can only be used in a sublimation printer.

Can I use sublimation paper for heat transfer?

We do not recommend using sublimation paper for heat transfer. Although the sublimation process requires heat and pressure to transfer dyes, but sublimation papers are printed using special dyes. Only use transfer paper for heat transfer projects.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023