I’ve always been a fan of leather products. They’re stylish, durable, and can be customized to fit my personality. But leather items are mostly available in limited designs. That is, until I discovered sublimation on leather.

Sublimation on leather opens up a world of designing possibilities, allowing you to imprint designs onto a variety of leather products and create truly custom items that are unique to you. Whether it’s customizing wallets, belts, hat patches, shoes, or even luggage tags, the possibilities are endless.

But when I first started out, I was a little intimidated by the process. There were so many different factors to consider, and I didn’t want to ruin my first project. That’s why I decided to write this guide to share my personal experience with sublimation on leather. I’ll show you how to choose the right materials, and transfer your favorite design onto leather.

Contents

- Can You Sublimate on Leather?

- Sublimation on Genuine Leather

- How to Sublimate on Genuine Leather

- Sublimation on Synthetic Leather (Faux Leather)

- Comparison of Genuine Leather and Faux Leather for Sublimation

- Tips and Tricks for Sublimating on Leather

- Sublimation on Leather Shoes

- Sublimation on Leather Wallets

- Can You Sublimate on White Faux Leather?

- Can You Sublimate on Suede?

- Conclusion

- Frequently Asked Questions

Can You Sublimate on Leather?

Yes, you can sublimate on leather. In fact, sublimation on leather is a great way to create custom and personalized leather products. I’ve been experimenting with leather sublimation for a few months now, and I’ve been really impressed with the results, especially on white leather.

Through the sublimation process, dyes are transformed into gas under controlled heat and pressure, penetrating the leather surface and resulting in vibrant and durable prints.

One crucial fact to note is that sublimation on leather is highly dependent on the type of leather you are working with. Genuine leather, with its natural grain and texture, offers a captivating canvas for sublimation. Its porous nature allows the dyes to penetrate and create beautiful prints.

On the other hand, synthetic leather, such as faux leather or polyvinyl chloride (PVC) leather is great for sublimation. This is because the surface of these leather-like materials are smooth and have polymeric properties, making them well-suited to absorb sublimation dyes.

And the good news, with the increasing popularity of sublimation printing, many manufacturers are producing leather sheets having a polymer coating on the surface. Such leather is sublimation ready, and I’ve observed that they are best to transfer designs onto.

Sublimation on Genuine Leather

Picture this: a beautifully crafted leather wallet, adorned with a vibrant, custom-designed pattern that reflects your unique style and personality. It’s a sight to behold, a statement piece that speaks volumes about your individuality.

This captivating transformation is made possible through the art of sublimation on genuine leather. This fascinating process combines artistry, craftsmanship, and a touch of magic.

How to Sublimate on Genuine Leather

Preparation of Real Leather for Sublimation

Start by selecting high-quality leather with a smooth and even surface. Gently clean the leather using a mild leather cleaner and a soft cloth, removing any dust or dirt. This step ensures a clean canvas for the sublimation process.

Next, apply a specialized leather pre-treatment solution. This solution helps open up the pores of the leather, allowing for better ink absorption and vibrant color transfer. I prefer NGOODIEZ Sublimation Coating, it works best on leather.

Using a soft brush, evenly spread the pre-treatment solution on the leather surface and let it dry completely before proceeding to the sublimation process.

Sublimation Process on Genuine Leather

The sublimation process on genuine leather requires specific materials and equipment. Begin by selecting sublimation inks specifically formulated for leather applications. These inks offer excellent adhesion and longevity on leather surfaces.

I personally prefer Hiipoo sublimation ink for all customization, they are vibrant and fade-resistant, giving long lives to my prints. Load the sublimation ink into a printer with dedicated heat-resistant sublimation paper. Now print your design and set it aside.

Set the heat press machine’s temperature to 375°F to 400°F depending on the thickness of the leather sheet. Carefully place the pre-treated leather on a heat press machine, ensuring it lies flat and taut.

Position the sublimation paper with the desired design on top of the leather and secure it with heat-resistant tape, ensuring a smooth and even placement.

Now, it’s time to apply heat and pressure, place a protective sheet on top of the sublimation paper and press for 50 seconds (that’s enough). Once the machine sets off, release the press and warm peel the sublimation paper to reveal your beautiful design on the leather.

Here’s an easy guide to do sublimation at home.

Sublimation on Synthetic Leather (Faux Leather)

As we have seen that sublimation is possible on genuine leather, how about faux leather? Yes, you can sublimate on synthetic leather too, also known as faux leather or PU leather.

In fact, faux leather is perfect for sublimation. I’ve noticed that sublimating on faux leather has allowed me to explore a wider range of creative possibilities while maintaining a budget-friendly approach.

How to Sublimate on Faux Leather

The sublimation process on faux leather is similar to that of genuine leather. However, the advantage of working with faux leather lies in its consistency and uniform surface.

Faux leather is typically made from a base fabric coated with a polyurethane layer, which creates an ideal substrate for sublimation. The ink easily penetrates the surface, resulting in sharp and durable prints.

To begin, select a high-quality faux leather material that is specifically designed for sublimation. Ensure that the surface of the faux leather is clean and free from any dirt or oils.

Create or select your design, and print it on a sublimation paper using a sublimation paper and sublimation ink.

Now it’s time to transfer the design to the faux leather sheet. Place the faux leather on the pre-heated heat press machine at 375°F temperature. Place the transfer paper with the design facing down onto the faux leather and secure it in place using heat-resistant tape. It is advised to place a protective paper sheet on top before applying heat.

Now, set the temperature at 375°F to 400°F and time for 40 seconds, you can increase the time to 45 seconds depending on the thickness of the faux sheet. Press the machine and let the heat and pressure do it’s magic.

Once the machine sets off, carefully remove the sublimation paper while it is still hot and admire your beautiful print on faux leather.

Comparison of Genuine Leather and Faux Leather for Sublimation

When comparing sublimation on real leather and faux leather, each has its unique advantages. Real leather offers a natural and luxurious feel, with its variations in texture and appearance. However, sublimating on genuine leather requires more caution and expertise due to its unpredictable nature.

On the other hand, faux leather provides consistent results and is more forgiving during the sublimation process. It allows for intricate designs and sharp details without compromising durability.

Additionally, faux leather is more accessible and cost-effective, making it an attractive option for businesses and individuals alike.

Here’s a comparison table highlighting the key differences between sublimation on genuine leather and sublimation on faux leather:

| Aspect | Sublimation on Genuine Leather | Sublimation on Faux Leather |

| Material Characteristics | Natural grain, texture, and porosity | Uniform surface, non-porous |

| Ink Absorption | Excellent ink absorption | May require additional care for ink absorption |

| Printing Results | Rich, vibrant prints | Vibrant prints with proper techniques |

| Surface Preparation | Cleaning is important for optimal results | Cleaning is important for proper ink adhesion |

| Cost | Relatively higher cost | More cost-effective option |

| Availability | Limited availability of genuine leather | Widely available in various colors and finishes |

| Design Flexibility | Natural variations enhance design appeal | Offers versatility in colors and textures |

| Durability | Durable and long-lasting | Durability varies based on quality |

| Applications | Various leather products and accessories | Bags, upholstery, and fashion accessories |

| Aesthetics | Organic, luxurious look and feel | Can mimic the appearance of genuine leather |

Tips and Tricks for Sublimating on Leather

To achieve exceptional results when sublimating on genuine leather, consider these tips and tricks:

- Before proceeding with the final design, it’s advisable to perform test prints on small leather scraps to determine the ideal temperature, time, and pressure settings.

- Genuine leather has a natural grain and texture that adds character to the final print. To fully leverage this, utilize high-resolution designs that can capture complex details and enhance the visual appeal of the finished product.

- Pay attention to temperature and pressure settings. Make sure the heat press machine is pre-heated at 375°F.

- Genuine leather is a premium material that requires delicate handling. Avoid excessive heat and prolonged exposure to prevent scorching or damaging the leather. Find the balance between sufficient heat for ink transfer and protecting the integrity of the leather.

- After sublimation, allow the leather to cool down completely before handling or applying any finishing products. This ensures the colors are set properly and reduces the risk of smudging or smearing.

Sublimation on Leather Shoes

Do you want to add a personal touch or bold statement to your footwear? Sublimating on leather is the answer to your desires.

I have customized a pair of classic leather shoes for parties, to stand out from the crowd. You can sublimate your designs, photos, or artwork onto genuine leather shoes, such as sneakers, boots, or loafers, creating a truly unique and one-of-a-kind pair of shoes.

The process of sublimating on leather shoes is relatively simple. First, you need to create your design (it’s better to use sublimation software). After that, print that design on sublimation paper using a sublimation printer and sublimation ink. Make sure to use specialized ink that is good for leather printing.

Once your design is on the sublimation paper, you need to place it on the shoe. Make sure that the shoe is smooth and free of wrinkles. Place the paper on top of the show where you want to print the design, and secure it using heat-resistant tape.

For best sublimation results on leather, make sure to preheat the heat press machine to 375°F temperature. Then, you need to heat press the shoe. The heat press will transfer the sublimated image to the shoe.

The amount of time that you need to heat press the shoe will vary depending on the thickness of the shoe. However, I usually heat press for about 30 to 40 seconds.

Once the shoe has cooled, you can peel off the sublimation paper. And that’s it! You’ve now sublimated your design onto a pair of leather shoes.

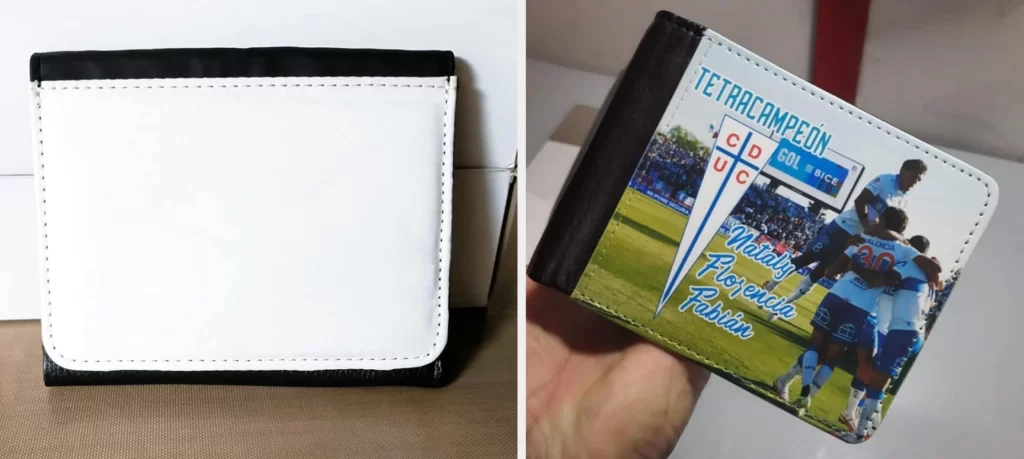

Sublimation on Leather Wallets

Leather wallets are not just functional accessories; they can also serve as a canvas for self-expression. Sublimating on leather wallets allows you to showcase your style and personality through vibrant and long-lasting designs.

When sublimating on leather wallets, I found that selecting the right wallet material is the key. Genuine leather wallets with a smooth finish tend to produce the best results. However, you can sublimate on faux leather wallets too.

Since a wallet is the most used and touched belonging, it is advised to pre-treat the surface before applying sublimation. This will not only make the prints bright, but ensure longevity to withstand the excessive touch and rubbing inside the pocket.

Clean the wallet surface thoroughly to remove any dust or oils that may restrain ink absorption. Remember to allow the wallet to dry completely before proceeding with the sublimation process.

Here, I do an extra step of applying sublimation coating on the leather surface. I prefer NGOODIEZ, you can use any that you trust.

Once the wallet is completely dry, just heat press it for 2 to 3 seconds just to remove all the wrinkles and make the surface smooth.

Now, print your design on a sublimation transfer paper, and cut the extra paper out for better placement since a wallet is a small item. Place the printed paper on the wallet where you want the design to be transferred and secure it using heat-resistant tape.

I always pre-heat the heat press machine and find it produces the best results, you can also follow this step for optimal results. Now, place the wallet on a heat press plate, set the temperature at 375°F to 400°F depending on the thickness of the wallet, and apply pressure for about 45 seconds.

That’s it, once the machine goes off, carefully remove the transfer paper and let the dyes dry completely before inserting the sublimated leather wallet in your pocket.

Note: keep in mind that some wallets may have compartments or zippers that can impact the sublimation process, so take care when positioning your design.

Here’s a guide on making sublimation brighter and more prominent.

The process of sublimation on faux leather earrings, baseballs, leather patches, and other leather products is almost similar. Just make sure to properly clean and pre-treat the surface for amazing results.

Can You Sublimate on White Faux Leather?

Absolutely, yes! You can sublimate on white faux leather.

Sublimating on white faux leather offers a unique advantage. The light base color allows the transferred design to truly pop and showcase vibrant colors.

However, for the best outcome, make sure you have a high-quality white faux leather sheet specially designed for sublimation. If not, apply a sublimation coating to make it a good recipient of sublimation dyes.

Can You Sublimate on Suede?

Yes, it is possible to sublimate on suede, but the results won’t be as bright as on other materials. Sublimating on suede presents some unique challenges compared to other types of leather. The soft and velvety texture of suede requires careful attention to ensure a successful outcome.

To sublimate on suede, understand that the ink will not penetrate the surface in the same way as it does on smooth leather. Instead, the ink sits on top of the suede fibers, resulting in a more muted and textured appearance. This characteristic can add a distinct and artistic touch to your designs.

I wasn’t amazed with the sublimation results on suede, colors were not vibrant or sharp as on other leather types. The texture of the suede slightly diffuses the colors, giving them a softer and more blended look. This effect can work well for certain artistic designs or vintage-inspired applications.

Conclusion

As we have seen that sublimation on leather opens up endless possibilities to customize your favorite leather products. A stunning printed design on classy genuine leather looks nothing less than art.

I have certainly witnessed the power of sublimation to breathe life into leather. From the vibrant prints on genuine leather wallets and shoes to the captivating designs on faux leather sheets, each creation becomes a unique expression of personal style and creativity.

Now, it’s your turn to follow this guide and unleash your creative potential, push the boundaries of your imagination, and let your designs speak volumes on the luxurious canvas of leather.

Frequently Asked Questions

What temperature do you sublimate on leather?

The recommended temperature for sublimating on leather typically ranges from 375°F to 400°F (190°C to 205°C), but it may vary depending on the specific leather type and thickness. I prefer sublimating at 375°F for about 40 to 45 seconds.

How do you sublimate PU leather?

To sublimate on PU leather, follow the same general process as sublimating on genuine leather. Ensure the surface is clean and free from dirt or oils, select sublimation inks compatible with synthetic materials. Print your design on a sublimation paper using a sublimation printer.

Now, place the printed design on a PU leather sheet and apply heat and pressure using a heat press machine. Recommended heat press settings for PU leather are 380°F temperature for 40 seconds.

Will sublimation work on faux leather?

Yes, sublimation can work on faux leather. Most of the faux leather sheets come sublimation ready. If you find a piece that is not a good recipient for sublimation dyes, you can pre-treat it with a sublimation coating.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023

What wasn’t mentioned in this article are sources for “high-quality white faux leather sheet specially designed for sublimation”. Can you provide references?

Thank you for pointing it out. Yes, you can try this white faux leather sheet that I mostly use for my personal items.