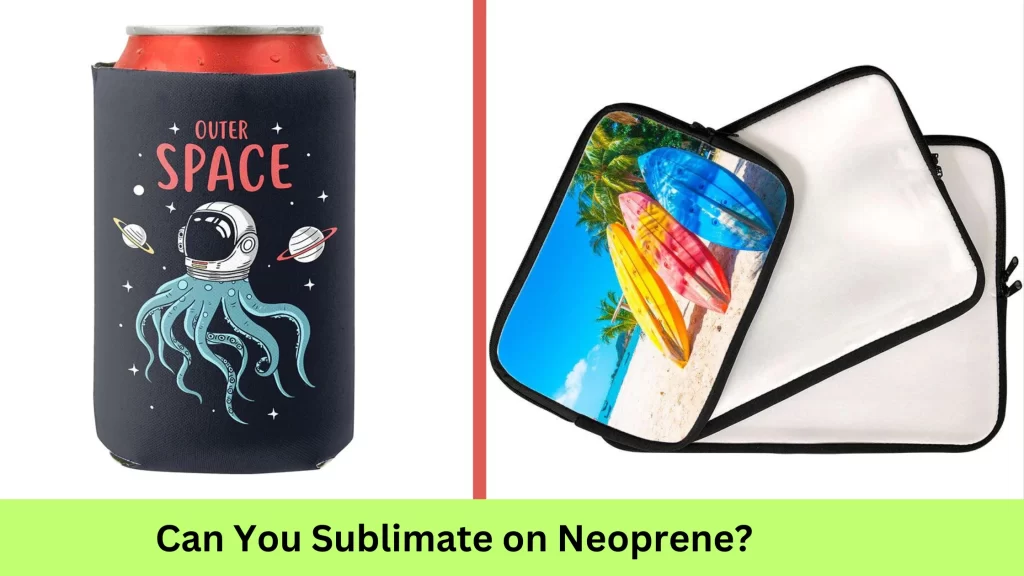

Do you want to personalize your can cooler or surf suit and wonder if you can sublimate on neoprene? Yes, you can! In fact, sublimation on neoprene is a great way to customize koozies and other neoprene fabric products. And let me tell you, sublimation on neoprene has been a game-changer for me.

When I first heard about the possibility of sublimating on neoprene blanks, I was amazed by the idea of turning bland wetsuits into eye-catching works of art.

Here, I’ll walk you through the process of sublimation on neoprene fabric, sharing insights from my personal experience, as well as tips and tricks I’ve picked up along the way.

Have you just started with sublimation printing? Here are the best sublimation printers for beginners in 2023.

Contents

Understanding Neoprene and How It is Good for Sublimation

Neoprene is a synthetic polymer material composed of polymerized chloroprene that is often used as a rubber alternative. It was first developed by DuPont in the 1930s to meet the demand for rubber, and has since gained immense popularity in various industries.

Let me tell you, neoprene’s reach extends far and wide! In the sports and fitness world, it’s the go-to for wetsuits, knee braces, and even stylish gym accessories.

Fashionistas adore it for its sleek look in clothing and accessories, especially in yoga pants and sauna suits.

What’s so awesome about it? Well, its unique properties are what make it perfect for sublimation. Here’s the lowdown:

Heat Resistance and Stability

Neoprene is very heat-resistant, and it can handle heat like a pro. Which means that it can withstand the high temperatures that are required for sublimation.

When we apply heat during sublimation printing, it remains stable, allowing our designs to fuse perfectly with the fabric. No worries about warping or melting here!

Flexibility and Stretchability

You know what they say, “Bend it like neoprene”. One of neoprene’s outstanding qualities is its exceptional flexibility and stretchability. It means our designs can handle movement on this material without cracking or fading.

For example, you could sublimate a design onto a neoprene wetsuit, activewear, neoprene sleeves, or other stretchable accessories.

Water Resistance and Durability

Neoprene is like a water warrior. It repels water like a champ, making it excellent for products that might encounter spills or splashes. Plus, it’s tough and long-lasting, ensuring our creations stand the test of time.

This unique property makes neoprene a good choice for sublimating items that will be exposed to water or wear and tear.

How to Sublimate on Neoprene

Alright, let’s get down to business and dive into the fantastic way to create vibrant and personalized designs on neoprene. Trust me, it’s a creative adventure you’ll absolutely love.

Here’s a step-by-step guide, with some helpful tips, to sublimate on neoprene like a pro:

Supplies Required

Before you begin, gather the following supplies:

- Sublimation printer

- Sublimation ink

- Sublimation paper

- Neoprene sublimation blank

- Heat press machine

- Heat resistant tape

- Protective paper (better to have)

Step-by-Step Guide for Dye Sublimation on Neoprene

Here’s the step-by-step process I followed to achieve vibrant sublimation results on neoprene:

Step 1: Preparing the Design

I let my creativity flow as I created or selected a design that perfectly matched the dimensions of my neoprene substrate. Whether it’s a custom graphic, a unique pattern, or a memorable photo, let your imagination soar.

You can use graphic design software like Adobe Photoshop or Illustrator to bring your ideas to life. I advise using software for sublimation that creates high-resolution graphics.

Step 2: Printing the Design

Load the sublimation paper into your printer, reverse your design and print it using sublimation ink. Ensure that the printer settings are optimized for the best color saturation and image quality.

The sublimation ink, when combined with the appropriate paper, will produce stunning and vibrant prints.

Well, I mostly use Sawgrass and Epson ET sublimation printers. Here are the Epson printer settings for sublimation if you are an Epson user.

Here are the best Epson printers for sublimation.

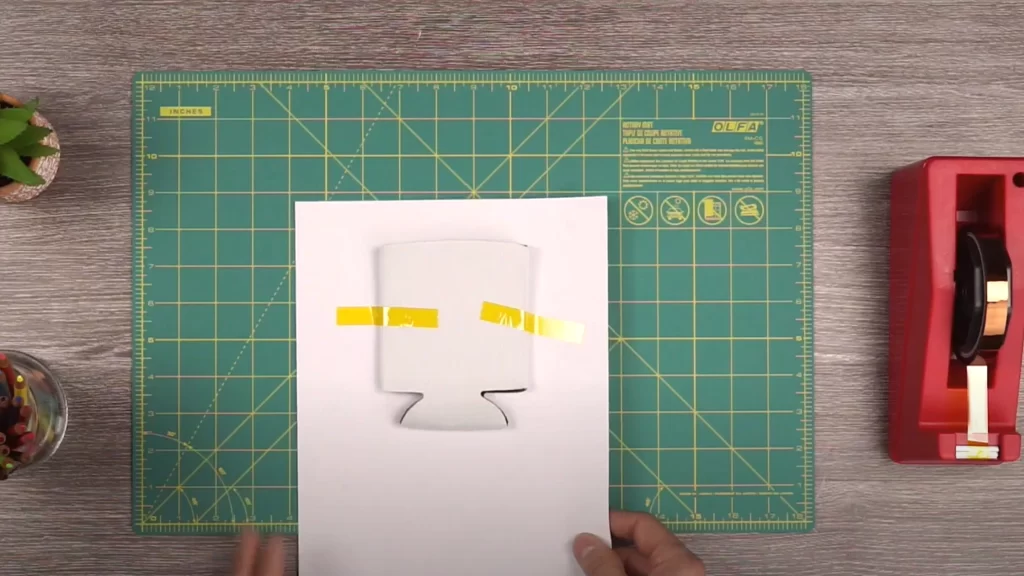

Step 3: Positioning and Securing the Neoprene Blank

Before setting up the sublimation paper on the neoprene blank, make sure it is free from dirt and wrinkles. Clean the substrate and iron it (if needed).

Place the neoprene substrate on a clean, flat surface. Carefully position the printed sublimation paper on top of the neoprene, aligning the design precisely as desired.

To ensure that the paper doesn’t shift during the sublimation process, use heat-resistant tape to secure the edges. This step is crucial for achieving accurate registration and preventing any unwanted movement.

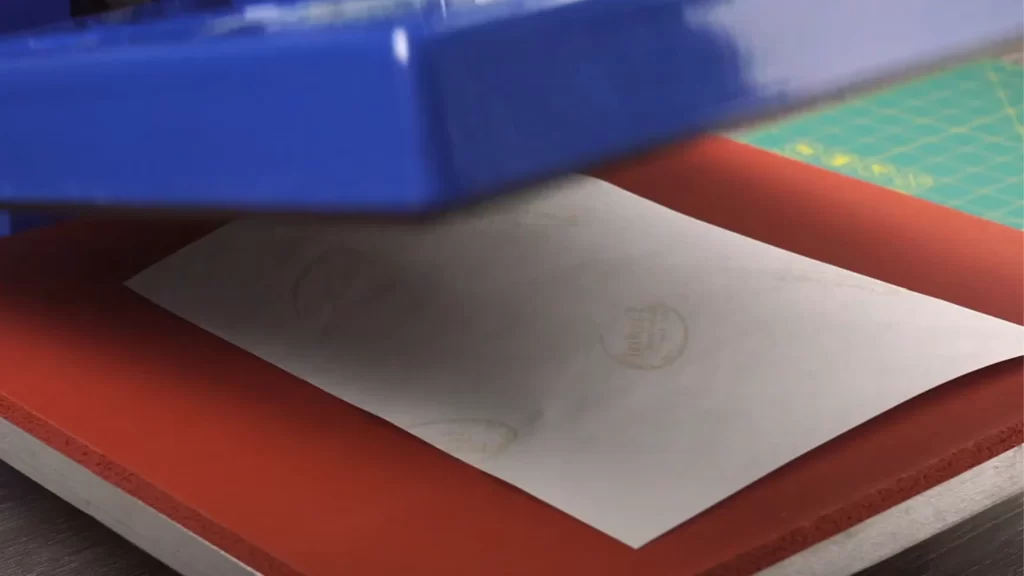

Step 4: Applying Heat and Pressure

I advise preheating your heat press machine to 400°F temperature. Once the heat press is ready, place the neoprene substrate with the secured sublimation paper onto the lower platen.

Now, close the press and apply temperature and pressure for 30 seconds, keeping the temperature setting at 400°F. The combination of heat and pressure will allow the sublimation ink to transfer from the paper onto the neoprene, creating a permanent bond.

Step 5: Cooling and Removing the Transfer Paper

After the sublimation process is complete, carefully lift the press with excitement. Give the substrate some time to cool down before removing the transfer paper. Cooling allows the ink to fully bond to the neoprene fibers, ensuring long-lasting and vibrant results.

Once cooled, gently peel off the transfer paper to reveal your stunning sublimated design on the neoprene surface.

Popular Neoprene Products for Sublimation

Here are some popular neoprene products that are commonly used for sublimation:

- Neoprene Can Koozies/Can Coolers

- Bottle Holders

- Mouse Pads

- Laptop Sleeves

- Neoprene Coaster

- Phone Cases

- Headphone Covers

- Sports Apparel (particularly for water sports like surfing, kayaking, canyoning, etc.)

- Bags and Pouches

- Sports Arm Sleeves

Can You Sublimate on Black Koozies?

I prefer using a white base layer to give my designs a bright foundation. This helps the colors pop and stands out beautifully against the black neoprene canvas.

Let me give you a little insight and suggestion to tackle sublimation on black neoprene koozies like a creative pro:

White Base Layer

As I mentioned above, using a white base layer is the easiest way to sublimate a black neoprene koozie. To ensure the colors of your design appear vibrant and true on a black background, a white base layer is essential.

And if you want even better results, use a clear or white vinyl sheet. This will provide a bright foundation for your colors to pop.

Read the guide on how to sublimate on vinyl.

Increased Dye Saturation

Dark surfaces tend to absorb more heat during the sublimation process. To achieve optimal results, increase the dye saturation in your design. This means adjusting the color intensity or increasing the percentage of color in your artwork to compensate for potential color loss during sublimation.

More Heat and Timing

Sublimation on black koozies requires a bit of extra effort. Black absorbs heat, so the usual temperature and timing might need some adjustments. Plus, remember that sublimation works best on lighter colors, so black neoprene might not give you the same vibrancy as lighter shades.

In addition, if the neoprene substrate is thicker than usual, it will again require more heat and pressure for a longer time to ensure the vibrancy of the colors.

Factors to Consider When Sublimating on Neoprene Fabric

When it comes to sublimating on neoprene, there are several crucial factors that can significantly impact the quality and success of your sublimated designs.

Drawing from my personal experience, let’s dive into these key considerations and explore how they can make a difference in your sublimation journey.

Choose the Right Type of Neoprene for Sublimation

The type of neoprene you choose for sublimation can impact the overall outcome of your designs. Smooth neoprene surfaces tend to yield sharper and more detailed sublimated prints, while textured neoprene can add a unique aesthetic appeal.

Thicker neoprene offers more durability and insulation, but it may require adjustments in temperature, time, and pressure settings. Thinner neoprene allows for quicker heat transfer but may be more prone to warping or wrinkling during the sublimation process.

Prepare the Neoprene Blank

Before sublimating, thoroughly clean the neoprene surface to remove any dust, dirt, or oils that could interfere with the ink transfer. A mild detergent or neoprene-specific cleaning solution can help ensure a clean surface.

After that, smooth out any wrinkles before sublimation, you can use the same heat press machine to flatten the material.

Temperature and Time Settings for Sublimation on Neoprene

Finding the sweet spot for temperature and duration often involves some experimentation and testing. It’s a delicate balance to ensure the ink fully sublimates without overheating the neoprene, which could cause undesired effects such as distortion or scorching.

A good starting point is to set the heat press to 385-400 degrees Fahrenheit and press for 30-45 seconds.

Pressure Considerations during Heat Pressing

Don’t overlook the pressure! It’s the key to ensuring the sublimation dyes bond evenly and beautifully to the neoprene surface. Too little pressure may result in incomplete or uneven sublimation, while excessive pressure could flatten the texture of the neoprene or cause unwanted imprints.

I recommend adjusting the pressure based on the thickness and type of neoprene you are using. Pay close attention to achieve a firm and even pressure distribution across the entire surface.

Post-Sublimation Finishing and Care

The joy of sublimation is complete once our designs come to life on neoprene! But, there’s a bit more to it – the post-sublimation finishing and care to keep our creations shining bright like diamonds.

A little trimming can give your neoprene products that professional touch. Snip away any excess material, so your designs look polished and neat. And if you want to go the extra mile, consider applying additional coatings or treatments for added protection and durability.

When washing, treat them gently – hand wash with a mild detergent or use a delicate cycle. Avoid harsh chemicals or bleach, as they can dull the colors. Once clean, dry them flat or hang them to dry – no tumble drying, please! Excessive heat exposure is a no-no. Avoid ironing or leaving them under the scorching sun, as it can impact the vibrant colors.

Oh, and remember, neoprene can be sensitive to abrasion, so handle them with care, and avoid rough surfaces or sharp objects.

Final Words

If you are still confused about if you can sublimate on neoprene or not, yes, you can! Equipped with the methods and knowledge shared here, you can confidently sublimate on neoprene blanks. Whether you are designing stunning activewear, personalized koozies, or sleek laptop sleeves, the possibilities are endless.

I have shared my experience, now its your turn to let your creativity run wild, experiment with designs, and create personalized neoprene products with incredible printing on it.

Frequently Asked Questions

Is neoprene polyester?

No, neoprene is not made of polyester. Neoprene is a synthetic rubber material that is composed of polychloroprene. It is not derived from polyester or any other textile material.

On the other hand, polyester is a type of polymer that belongs to the polyester family, which includes materials like polyethylene terephthalate (PET) and polybutylene terephthalate (PBT).

What temperature do you sublimate on neoprene?

For optimal sublimation results on neoprene, the recommended temperature range is typically between 380°F to 400°F (193°C to 204°C).

How long to press sublimation on neoprene?

The ideal pressing time during sublimation on neoprene is usually between 30 to 45 seconds depending on the thickness of the material.

Can you sublimate neoprene koozies?

Absolutely! Neoprene koozies are fantastic for sublimation printing. These versatile koozies provide a perfect canvas for showcasing your unique designs with vivid colors and excellent clarity.

Whether it’s for events, personalized gifts, or promotional items, sublimating neoprene koozies offer a fun and stylish way to elevate your creations.

What temperature and time for sublimation on neoprene koozies?

To sublimate neoprene koozies effectively, maintain a temperature range of 380°F (193°C) during the pressing process. Press the koozies for around 40 seconds, allowing the sublimation ink to transfer seamlessly onto the neoprene surface.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023

![Sublimation on Leather Products [Guide for Best Results] can you sublimate on leather](https://subliprinting.com/wp-content/uploads/2023/07/can-you-sublimate-on-leather-150x150.webp)

![How to Sublimate on Wood? Pro Tips & Best Method [Tested] wood sublimation](https://subliprinting.com/wp-content/uploads/2022/04/wood-sublimation-150x150.png)