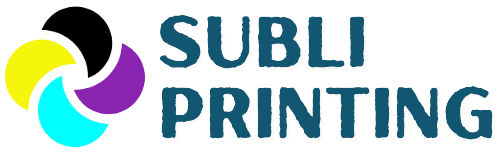

Are you struggling to decide between sublimation vs. screen printing for your apparel designing needs? Having been through the same puzzle myself, I understand the challenges that come with choosing the shirt printing method.

When I was first starting out, I decided to go with sublimation printing because of the fact that it can produce high-quality prints with vibrant colors. I also like the fact that the sublimation method is a relatively quicker and easier process as compared to screen printing, which meant that I could get my products to market faster.

However, sublimation isn’t without its drawbacks. For one, it can be more expensive than screen printing, and it is only suitable for certain types of materials, such as light-colored polyester.

To make you an informed decision, I’ll walk you through a comprehensive comparison of sublimation and screen printing, sharing true facts and insights based on my personal experience.

Also, read the comparison between DTG and sublimation printing.

Also, read about sublimation vs. heat press.

Contents

- Understanding Sublimation Printing

- Understanding Screen Printing

- Key Differences between Sublimation and Screen Printing

- Comparison Table between Sublimation vs. Screen Printing

- Factors to Consider When Choosing Between Sublimation and Screen Printing

- Which is Better Sublimation vs. Screen Printing?

- Final Words: Sublimation vs. Screen Printing

- Frequently Asked Questions

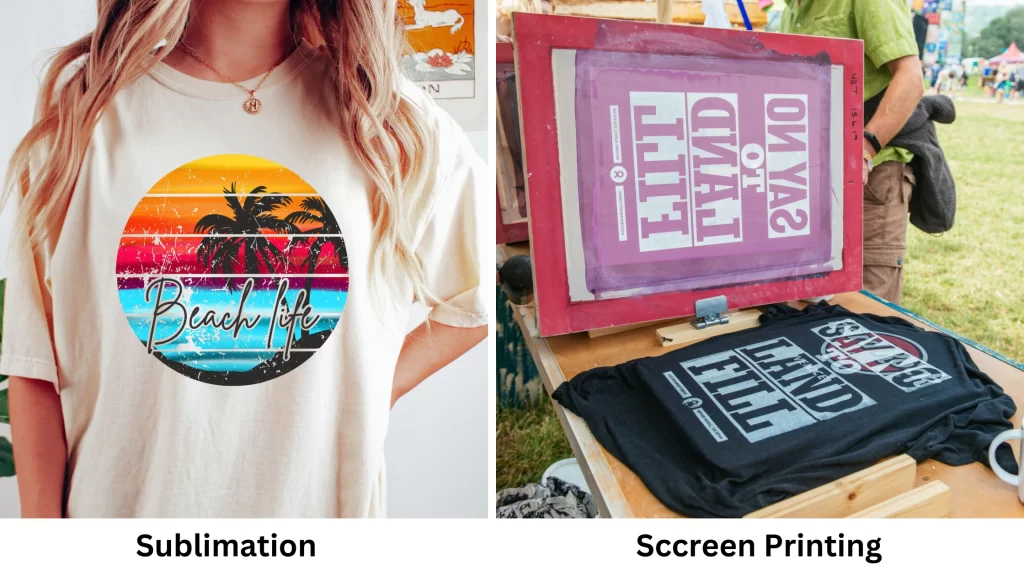

Understanding Sublimation Printing

At its core, sublimation is a cutting-edge technique that transforms ink into a gas state without passing through a liquid phase.

The ink used in sublimation printing is a special type of dye that vaporizes when heat and pressure are applied. When the vaporized ink comes into contact with a substrate that is compatible with sublimation, the ink molecules are absorbed into the substrate and become a permanent part of the material.

The possibilities with sublimation printing are practically limitless, especially when it comes to polyester or polyester-coated materials. From trendy apparel like custom t-shirts and jerseys to home decor items like cushions, mugs, and wall art, sublimation lets you unleash your creativity and bring your designs to life in ways you never thought possible.

The only limitation is that the substrate material must be compatible with sublimation printing. This means that the material must be able to absorb the vaporized ink. Most synthetic fabrics, such as polyester, are compatible with sublimation printing. However, some natural fabrics, such as cotton, are not.

Understanding Screen Printing

Screen printing is a method that involves using a mesh screen to transfer ink onto various surfaces. This process allows for the creation of bold, opaque designs with exceptional precision and durability.

Unlike sublimation printing, which penetrates the fabric, screen printing lays ink on top of the material, creating a vibrant layer of color.

Let me break it down for you. Imagine you want to print your artwork on a t-shirt, that’s where screen printing comes into play.

First, a fine mesh screen is prepared with your design by creating a stencil-like template. This template is attached to the screen, which acts as a filter to allow ink to pass through in specific areas. Then, the screen is placed on top of the material you want to print on, like the t-shirt.

Next comes the ink. It’s applied onto the screen and spread across its surface. With the help of a squeegee, the ink is pressed through the stencil, transferring the design onto the material beneath. The result is a sharp, vibrant image that adheres firmly to the fabric.

The versatility of silk screen printing is impressive. It’s not limited to just t-shirts only; you can use this method to print on various textiles, such as hoodies, tote bags, and even promotional items like posters and banners.

One of the key advantages that I love about screen printing is that it is not limited to only light-colored fabrics, you can design any color fabric using this method.

Video Guide on Screen Printing

Key Differences between Sublimation and Screen Printing

The key difference between screen printing and sublimation printing is the level of detail in the final print.

With sublimation printing, the printer prints onto specially designed heat transfer paper. The prints stand out with their vibrant colors, exceptional detail, and durability. It’s a quick process that can print 1-6 colors at once.

This means that it’s perfect for businesses that want to print in bulk. And, it offers a fantastic level of detail and complicated designs.

In the case of screen printing, the printer will use a screen that is silk-screened with ink. This allows for fine details to be printed on, as well as any complex designs. However, this process is slow and limited to 1-4 colors per print.

Having personally experienced both techniques, let’s dive into the key differences to help you make an informed decision.

1. Print Quality and Durability

Sublimation printing offers exceptional print quality and durability. These prints retain their sharpness, vivid colors, and resistance to fading, washing, and general wear and tear for a long time.

Screen printing, known for its durability, can produce solid, opaque prints that withstand repeated washes and maintain their color vibrancy over time. However, complex designs sharp details may not be as precise as in sublimation prints.

2. Print Complexity

Sublimation is highly capable of handling complex designs with fine details, gradients, and photographic images. It can reproduce subtle color variations and difficult patterns accurately.

On the other hand, screen printing is better suited for bold, solid designs with limited color variations. It involves layering separate screens for each color, which may not capture the same level of detail as sublimation.

3. Number of Colors

Sublimation allows for an unlimited number of colors and smooth color blending. Since it uses a full-color spectrum, there are no limitations on the color variations within a design.

Plus, sublimation is done using CMYK colors and the printing software adjusts the ICC profile. The colors are always sharp and prints come out with full colors.

On the other hand, screen printing is typically limited to a specific number of colors per design. Each color requires a separate screen and printing pass, which can increase production time and cost.

Color blending in silk screen printing is achieved by overlapping solid colors, resulting in a slightly different effect compared to the seamless transitions possible with sublimation.

Read how to make sublimation brighter.

4. Special Effects

This is where I prefer screen printing over sublimation. Sublimation printing focuses on producing full-color, high-resolution prints and does not typically offer specialty inks or effects like metallic, glow-in-the-dark, or raised textures.

In contrast, screen printing allows for the use of various specialty inks and techniques. For example, metallic inks can add a reflective sheen, glow-in-the-dark inks create luminescent effects, and puff inks create raised textures that add dimension to the design.

5. Fabrics and Materials

If only sublimation could have been done on any color or material, I would have said goodbye to all other printing methods. But pity, there are some limitations.

Sublimation works best on polyester-based materials because the ink chemically bonds with the synthetic fibers, resulting in vibrant, permanent prints. However, it is not suitable for natural fibers like cotton or fabrics with a low polyester content.

Yes, it’s true that you can sublimate on ceramic mugs, metal tumblers, acrylic and wood blanks, etc. but they all must be coated with a special solution to bond with sublimation ink.

Screen printing can be applied to a wide range of fabrics, including cotton, polyester, nylon, blends, and even rigid surfaces like wood or metal. This versatility makes screen printing a popular choice for various apparel and promotional items.

Read instructions to sublimate on nylon.

6. Eco-Friendliness

If you are an eco-friendly person, I’d recommend leaning toward the sublimation method. Sublimation uses water-based inks that have a minimal environmental impact, and the printing process produces little to no waste, as the ink is fully absorbed into the fabric.

In screen printing, some processes may involve the use of solvents or plastisol inks, which can have a higher environmental footprint.

7. Printing Quantity

Both sublimation and screen printing is best suited for large quantity shirt printing. In sublimation, you can print the same design as many times as you want and heat press to transfer on fabric in large quantities. Once the design is ready, the t-shirt printing processing time remains the same.

Screen printing, on the other hand, is more efficient for larger production runs due to its setup requirements. The time-consuming nature of screen preparation and color registration makes it better suited for higher quantities where the cost per unit decreases with economies of scale.

If you’ve messed up with sublimation, here’s a guide to remove sublimation ink from different substrates.

8. On-Demand Fulfillment

Sublimation is highly suitable for on-demand fulfillment and quick customization. Since the printing process is digital, there is no need for additional setup or screen changes for different designs.

You can easily create unique designs and print them as needed, which is particularly useful for personalized products and small-scale operations.

Screen printing, while it allows for customization, may have longer lead times due to the screen setup and color registration process, making it more suitable for bulk production or pre-planned designs.

9. Cost Efficiency

The cost efficiency of each method depends on various factors such as design complexity, quantity, and production setup. For small quantities or designs with multiple colors and gradients, sublimation printing may be more cost-effective due to its minimal setup requirements.

As the quantity increases, screen printing becomes more cost-efficient due to economies of scale. Silk screen printing also offers potential cost savings for simple designs with limited color variations.

10. Consistency

I like the consistency of the sublimation printing process because it ensures consistent color reproduction across multiple prints. The digital nature of the process allows for precise color matching and replication.

In screen printing, slight variations in color and placement may occur due to factors like ink mixing, screen alignment, and the manual aspect of the process. However, experienced screen printers can maintain a high level of consistency through meticulous color management and quality control.

11. Items Required

Sublimation requires quite a specialized setup for printing, including sublimation inks, a sublimation printer, heat press equipment, and appropriate polyester-based sublimation-ready substrates.

Screen printing, on the other hand, involves screens, frames, stencils or emulsions, inks, a squeegee, and a screen printing press or setup for manual printing.

Additionally, screen printing may require exposure units and washout stations for screen preparation and cleaning.

12. Set-Up Time

Sublimation printing has a relatively quick setup process since it involves minimal equipment preparation and no screen preparation. The main time-consuming step is printing and heat pressing each design.

Screen printing, on the other hand, requires more time for screen preparation, including applying emulsion or stencil, exposing the design, aligning screens for multi-color prints, and mixing inks. The set-up time for screen printing can be more significant, especially for designs with multiple colors.

Comparison Table between Sublimation vs. Screen Printing

Here’s a comparison table between sublimation and screen printing:

| Factors | Sublimation Printing | Screen Printing |

| Print Quality | High-resolution prints with vibrant colors | Solid, opaque prints with excellent color vibrancy |

| Durability | Long-lasting prints resistant to fading and wear | Durable prints that withstand repeated washes |

| Design Complexity | Ideal for intricate designs and fine details | Suitable for bold and simple designs |

| Color Options | Unlimited colors and seamless color blending | Limited number of colors per design |

| Fabric Compatibility | Best suited for polyester-based materials | Compatible with a wide range of fabrics |

| Production Volume | Suitable for small to medium quantities | Cost-effective for larger production runs |

| Cost Efficiency | Cost-effective for small quantities or custom prints | More cost-effective for larger quantities |

| Setup Time | Quick setup with minimal equipment preparation | Longer setup time for screen preparation and alignment |

| Environmental Impact | Water-based inks with minimal environmental impact | Some processes may involve solvents or plastisol inks |

| Specialty Effects | Limited availability of specialty inks or effects | Offers a variety of specialty inks and effects |

| Applications | Sublimation can be used to print on a wide range of substrates, including t-shirts, mugs, metals, hats, bags, and more. | Screen printing is best suited for printing on fabric. |

| Skill Level | Sublimation is a relatively easy printing method that can be learned by beginners. | Screen printing can be more difficult to learn. |

Factors to Consider When Choosing Between Sublimation and Screen Printing

When deciding between sublimation and screen printing, there are several important factors to consider that can help you make the right choice for your specific needs.

Fabric Type

For sublimation printing, light-colored polyester and polyester blends are the ideal fabric choices. The ink used in sublimation printing bonds directly with these synthetic fibers, resulting in vibrant and long-lasting prints.

On the other hand, screen printing is well suited for all types of fabric, including cotton and other natural fibers, as it provides excellent opacity and durability on these materials. Plus, you can design dark-colored garments nicely.

Design Complexity

If your design includes intricate details, fine lines, or gradients, sublimation printing is the way to go. The sublimation process allows for precise color blending and seamless reproduction of complex designs.

However, if your design is bold and simple with one color, screen printing can deliver solid colors and clear lines effectively.

Color Requirements

Sublimation printing can produce vibrant and unlimited colors. If your design calls for vibrant and a lot of colors, sublimation printing is the answer. It allows for the use of a wide color range and smooth color transitions.

On the other hand, for solid and opaque colors, such as in corporate logos or sports team jerseys, I prefer screen printing because it can provide excellent color coverage.

Production Volume and Budget

If you have a large production volume and need to optimize your budget, screen printing is the cost-effective choice. Screen printing allows for efficient mass production, with lower costs per unit as the quantity increases.

However, if you require small to medium quantities or need to offer custom prints, sublimation printing offers flexibility and on-demand capabilities without incurring high setup costs.

Which is Better Sublimation vs. Screen Printing?

When it comes to comparing sublimation and screen printing, it’s important to note that both methods have their strengths and suitability depending on specific factors. Based on personal experience, below is some insight to find the better printing method between these two.

Sublimation has been my preferred choice for complex designs and vibrant colors. The ability to reproduce fine details, gradients, and photorealistic images with exceptional quality is a major advantage of sublimation.

The durability of sublimation prints is also impressive, as they resist cracking, peeling, and fading over time. Additionally, the on-demand fulfillment capability of sublimation has allowed me to cater to custom printing needs efficiently.

On the other hand, screen printing has proven its worth for simpler, bold designs and larger production runs. The solid and opaque prints produced by screen printing have excellent durability and color vibrancy.

With precise color matching, screen printing can deliver consistent results. It has also provided cost advantages for bulk orders, as the setup time can be spread across a larger quantity of prints.

Final Words: Sublimation vs. Screen Printing

After having experience with both sublimation and screen printing in my business, I can confidently say that each method offers unique advantages and is suited to different printing requirements.

Sublimation printing excels in producing detailed, high-quality designs with vibrant colors on polyester-based materials, making it ideal for custom and on-demand printing. Its ability to reproduce photorealistic images and withstand repeated washes has been a significant asset for personalized and durable products.

On the other hand, screen printing has proven to be a reliable choice for larger production runs and simple, bold designs. Its solid prints, coupled with cost-effectiveness for bulk orders, have made it a go-to method for certain projects.

Frequently Asked Questions

Is screen printing more expensive than sublimation?

Screen printing can be more cost-effective for larger production runs due to economies of scale. However, for smaller quantities or customized prints, sublimation printing offers cost advantages since it eliminates the need for multiple screens and allows for on-demand fulfillment.

What is the disadvantage of sublimation printing?

One potential disadvantage of sublimation printing is its limited compatibility with natural fibers such as cotton. Sublimation inks chemically bond with synthetic polyester fibers, resulting in vibrant and durable prints.

In addition, sublimation is not good for dark-colored garments because the colors will not be accurate as they appear in designs.

What’s better than sublimation?

The notion of something being universally “better” than sublimation depends on the specific requirements of your project. However, if you are looking for an alternative, direct-to-garment (DTG) printing can be a suitable option.

DTG printing offers high-resolution, full-color prints on a wide range of fabrics, including cotton. It allows for intricate details and is ideal for small to medium quantities. Consider the fabric type, design complexity, and color requirements to determine the best printing method for your specific needs.

Which printing method offers better print quality and durability: sublimation or screen printing?

Sublimation printing generally offers better print quality and durability compared to screen printing. Sublimation ink penetrates the fibers of the material, resulting in vibrant and long-lasting prints that resist fading, cracking, and peeling.

On the other hand, screen printing creates a layer of ink on top of the fabric, which may not be as durable over time, especially with frequent washing and wear.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023