Sublimation printing has revolutionized the world of customization. I’ve been using it for years to create personalized gifts and home décor. Recently, I’ve been experimenting with sublimating on microfiber cloth including towels and pillowcases, and I’m really excited about the potential of this technique.

Microfiber is a very soft and absorbent fabric, which makes it ideal for kitchen and beach towels, and other household items. It is also a polyester fabric, which means that it is compatible with sublimation printing.

In this article, I aim to unveil the hidden potential of sublimating on microfiber fabric, highlighting its exceptional absorbency, velvety texture, and high-resolution image transfer capabilities. Let’s get creative and explore the benefits that sublimating microfiber can offer.

Also, read if you can sublimate on neoprene.

Contents

- Microfiber as a Sublimation Substrate

- Can You Sublimate on Microfiber? Truth Revealed

- How to Sublimate on Microfiber Towel – Best Method

- Step by Step Guide to Sublimate on Microfiber

- Best Suited Dye-Sublimation Inks for Microfiber

- Tips for Achieving Best Sublimation Results on Microfiber

- Potential Applications of Sublimated Microfiber Products

- Conclusion

- Frequently Asked Questions

Microfiber as a Sublimation Substrate

Microfiber fabric, with its remarkable softness, exceptional absorbency, and fine texture, has been revolutionizing the textile industry. Composed of ultra-fine synthetic fibers, usually a blend of polyester and polyamide, microfiber boasts an intricate structure that sets it apart from conventional fabrics.

Its densely woven composition allows for vibrant and detailed prints, making it a good choice for sublimation printing. It is also a relatively inexpensive fabric, which makes it a popular choice for bath, beach, and kitchen towels, clothes, and other household items.

While microfiber proves to be a versatile substrate, certain challenges should be considered. Its dense structure can lead to slower dye diffusion during the sublimation process, demanding precise time and temperature control.

Additionally, color matching may differ slightly from other materials, requiring adjustments in the design process.

However, with proper understanding and calibration, these challenges can be overcome, unlocking the full potential of sublimation on microfiber.

Types of Microfiber Fabrics and Their Impact on Sublimation

Microfiber comes in various types, each type offers distinct advantages in the sublimation process. Microfiber types are:

- Suede

- Terry

- Smooth

Suede microfiber provides a luxurious surface for complex designs, while terry microfiber excels in moisture-wicking properties, ideal for towels and athletic apparel. Smooth microfiber, on the other hand, presents a sleek canvas for vivid graphics.

Can You Sublimate on Microfiber? Truth Revealed

Yes, you can sublimate on microfiber. Sublimating on microfiber fabric is not only possible but also opens up exciting ways to personalize your towels and other garments.

Microfiber is made from ultra-fine synthetic fibers, typically a blend of polyester and polyamide (nylon). This composition makes microfiber incredibly soft, lightweight, and highly absorbent.

As sublimation inks are primarily designed to bond with polyester, the polyester content in microfiber enhances the ink’s adhesion, leading to sharp and vivid prints.

But wait, there’s more! Sublimation on microfiber isn’t limited to just one type of fabric. You can explore a wide variety of microfiber fabrics with different weights, textures, and finishes. Whether it’s a luxurious microfiber towel for the spa, a sporty microfiber cloth for fitness enthusiasts, or a smooth microfiber fabric for home textiles, the options are endless.

Now, I won’t sugarcoat it; there are a few challenges to be mindful of when sublimating on microfiber. The fabric’s absorbent nature can affect ink transfer during the sublimation process, leading to slightly muted colors.

However, with the right techniques and heat press adjustments, you can overcome this obstacle and achieve stunning results.

Read about good materials for sublimation.

How to Sublimate on Microfiber Towel – Best Method

Let’s go through the step-by-step guide for sublimating on microfiber:

Supplies Needed

- Microfiber Towel or Cloth

- Dye-Sublimation Inks

- Heat Press

- Sublimation Printer

- Sublimation Paper

- Lint Roller

- Protective Paper

- Heat Resistant Tape

- Heat-resistant Gloves

Pre-treatment Process: Cleaning and Preparing the Fabric Surface

Before diving into sublimation, starting with a clean slate is essential. Begin by carefully cleaning the surface of your microfiber towel. Remove any dust, debris, or lint using a lint roller to ensure a smooth and flawless fabric surface.

Here’s a key to success – pay attention to the polyester content in your microfiber towel. Sublimation inks have a special affinity for polyester fibers. The higher the polyester content in your microfiber, the better the ink adhesion and color vibrancy.

Aim for microfiber towels with a higher polyester blend to achieve stunning and long-lasting prints.

Step by Step Guide to Sublimate on Microfiber

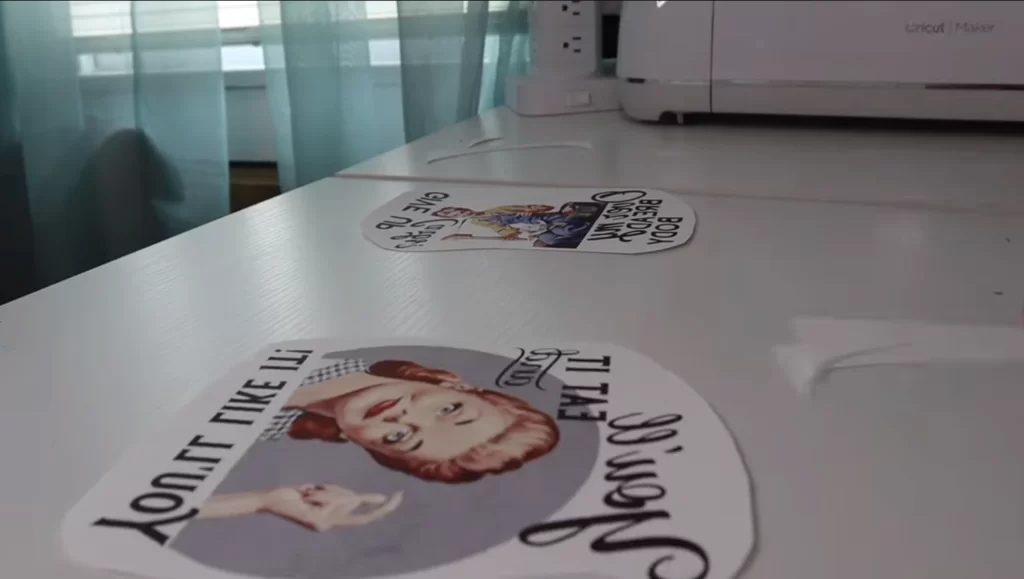

1. Design and Print

Get creative and design your artwork using sublimation software. Pay attention to color choices, resolution, and image size for optimal results.

Once you are satisfied with your design, print it onto the sublimation paper using your sublimation printer and inks. Remember to mirror the image to ensure it transfers correctly onto the microfiber fabric.

2. Prepare the Microfiber Surface

Lay your microfiber fabric flat on a clean and even work surface. Before proceeding, make sure the fabric is clean and free from any debris or contaminants.

Washing the microfiber with no fabric softeners or dryer sheets is essential to prevent any residue that might interfere with dye absorption during sublimation.

For best results, I spray a polymer sublimation coating to create a layer on top of the microfiber surface. It allows for maximum absorption and proper transferring the dyes.

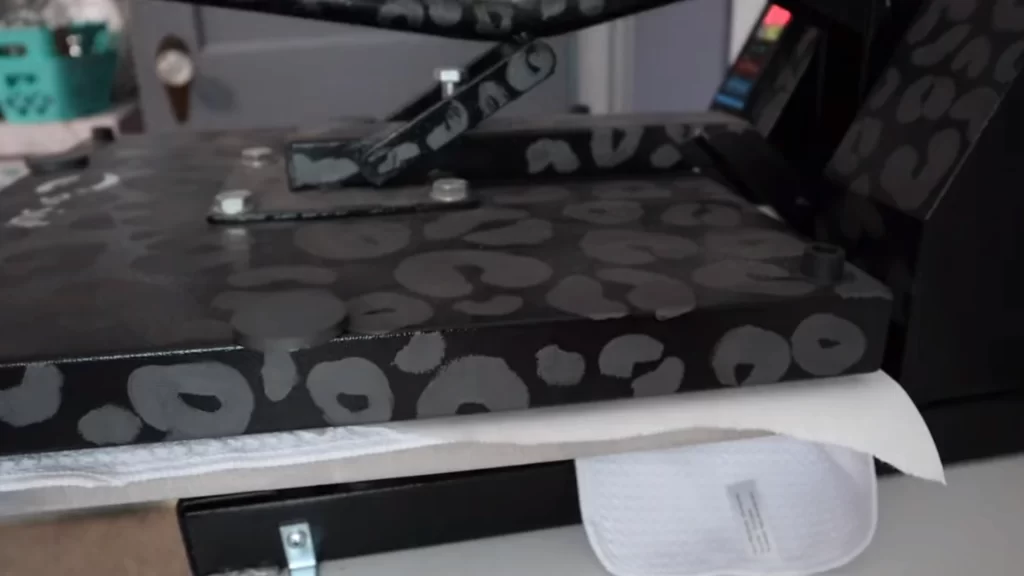

3. Pre-treat the Fabric

Before you sublimate your design onto the fabric, you need to pre-treat the fabric. This will help to ensure that the ink transfers evenly and that the colors are vibrant.

Set the heat press to 350°F and press the fabric for 30 seconds. It will remove all the wrinkles and smoothen the surface.

4. Position and Secure the Design

Carefully place the sublimation paper with the printed side facing down onto the microfiber fabric. Ensure that the design is positioned exactly where you want it on the fabric.

To prevent any shifting during the sublimation process, use heat-resistant tape to secure the sublimation paper to the microfiber.

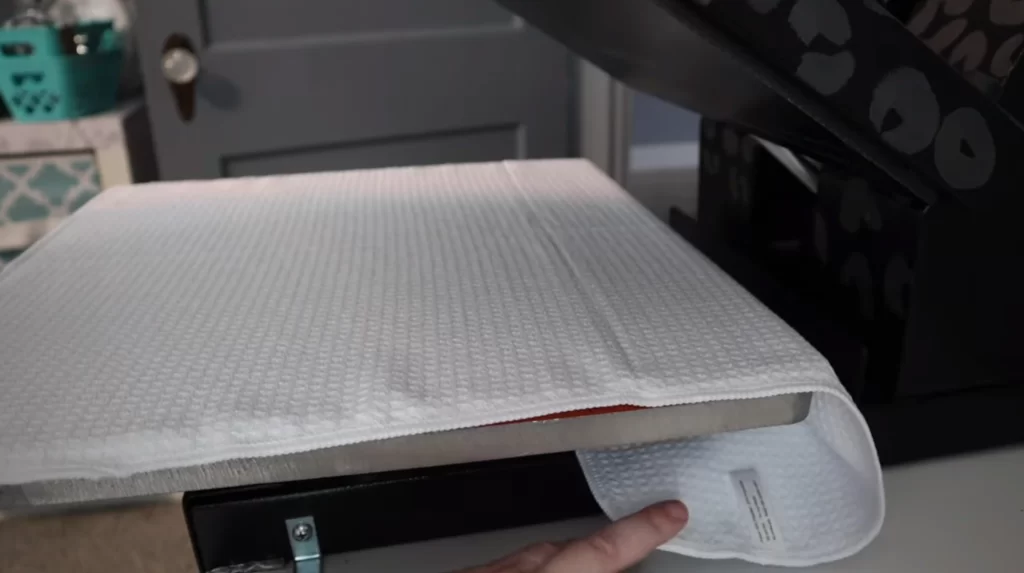

5. Heat Pressing

Now, it’s time to fire up the heat press machine! Applying even and firm pressure to the fabric is necessary, otherwise, the dyes will not transfer from all over as you expect them.

Carefully place the microfiber fabric with the secured sublimation paper onto the heat press platen. Place a protective sheet on top and set the heat press temperate at 400°F and time at 50 seconds, and close the heat press.

6. Cooling and Unveiling the Design

Once the pressing time is complete, carefully open the heat press and remove the microfiber fabric. Allow it to cool before gently peeling off the sublimation paper.

The moment of truth! As you peel back the paper, you’ll reveal your stunning and vibrant sublimated design on the microfiber fabric.

Video Tutorial on How to Sublimate on Microfiber Kitchen Towel

Best Suited Dye-Sublimation Inks for Microfiber

The best-suited dye-sublimation inks for microfiber are those that are specifically designed for use with polyester fabrics. These inks are typically made from a blend of dye and resin, and they have a high level of pigment concentration. This ensures that the colors are vibrant and that the prints are durable.

Some of the best-suited dye-sublimation inks for microfiber include:

- Sawgrass Virtuoso dye sublimation ink

- Sawgrass SG500 dye sublimation ink

- Hiipoo Sublimation Ink

These inks are all available in a variety of colors, and they are all compatible with most sublimation printers. They are also relatively affordable, making them a good option for budget-minded crafters.

Read a detailed post on best sublimation inks to find the suitable one for your needs.

Tips for Achieving Best Sublimation Results on Microfiber

I’ve got some tricks up my sleeve after multiple projects, to make sublimation brighter on microfiber! Let me spill the beans on how to achieve outstanding results and avoid common mistakes. Ready? Let’s dive in!

Avoid These Common Mistakes

- Using Low-Resolution Designs: Trust me, the secret to crisp prints on microfiber is high-resolution designs. Low-quality images can lead to blurry and pixelated prints. So, always aim for high resolution to make your designs shine!

- Misalignment Woes: Oh, I’ve been there! Poor alignment can ruin even the best designs. Make sure your print is correctly positioned on the microfiber substrate before sublimating. A slight shift can make a big difference in the final result.

- Neglecting Sublimation Best Practices: The key to vibrant and durable prints lies in the correct sublimation practices. From temperature and timing to pressure, follow this guide for the best outcome.

Make Your Prints Pop

- Utilizing High-Resolution Designs and Artwork: This one’s a game-changer! High-resolution designs ensure your prints come out sharp and detailed. When creating or choosing artwork for sublimation, aim for a minimum of 300 DPI (dots per inch).

- Properly Aligning the Print on the Microfiber Substrate: Precision is key! Take the time to align your print perfectly on the microfiber substrate before sublimation. Use guides or markers to ensure the design is centered and straight. Trust me, a well-aligned print can turn a good project into a masterpiece.

- Maximizing Color Vibrancy and Durability: To make those colors pop and stay vibrant wash after wash, make sure you are using high-quality dye-sublimation inks for microfiber. Also, follow the instructions step by step as I’ve explained in this post including settings – temperature, timing, and pressure.

I personally prefer Hiipoo sublimation inks with Epson EcoTank printer, it is the best combo. Here are the best Epson printers for sublimation – choose one and level up your printing results.

Potential Applications of Sublimated Microfiber Products

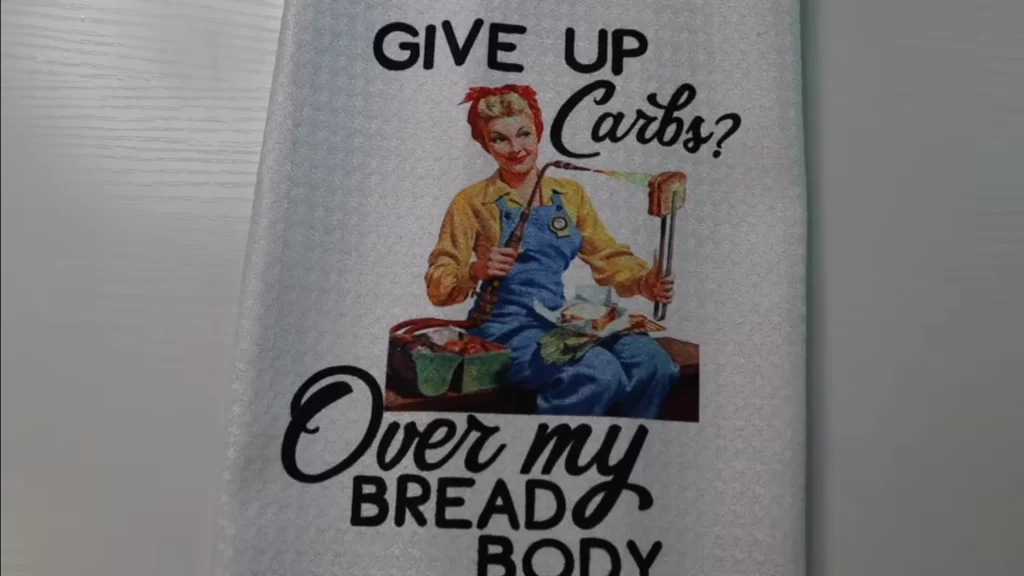

You might have seen some personalized kitchen or beach towels and thought sublimation on microfiber is limited to only this – but that’s not true! This technique has fantastic benefits and trust me, it’s like adding a touch of magic to everyday items.

In addition, the versatility and exceptional print quality make sublimated microfiber products a popular choice for businesses and individuals seeking personalized and visually striking items.

1. Customized Microfiber Towels for Fitness Industry

Picture this – personalized microfiber towels with your favorite sports team logo or your name on it!

Sublimation allows you to create custom-designed microfiber towels that are soft, absorbent, and perfect for sports and fitness enthusiasts. Whether it’s for the gym, yoga studio, or outdoor activities, these towels will keep you feeling fresh and stylish.

2. Personalized Microfiber Cloths for Promotional Merchandise

Looking to make a lasting impression with your brand? Sublimated microfiber cloths are your go-to solution!

These handy cloths are perfect for cleaning glasses, screens, and delicate surfaces. Adding your company logo to these clothes creates unique and valuable promotional merchandise that your customers will love.

3. Products for the Hospitality Sector

Here’s a little secret to boost your hospitality game – sublimated microfiber products! From luxurious hotel towels and spa robes to eye-catching tea towels, waffle towels, bath towels, and other tablecloths and napkins, sublimation creates a welcoming and stylish ambiance for your guests.

4. Products for Gifting Purposes

Gift-giving just got a whole lot more exciting! With sublimation, you can design personalized microfiber products that make heartfelt and unforgettable gifts.

Imagine gifting someone a soft and cozy microfiber blanket to a newlywed couple with their name on it or a charming set of custom-designed microfiber coasters for their home. It’s a thoughtful gesture that’ll warm their hearts!

Conclusion

Are you still confused if you can sublimate on microfiber fabric? “Absolutely, YES!” Through my personal experience, I’ve discovered the immense potential of this printing technique. You can indeed sublimate on microfiber towels and other clothes.

Through high-resolution designs, proper alignment, and the right dye-sublimation inks, vibrant and durable prints come to life. The applications are vast, from personalized sports towels to promotional merchandise and hospitality products.

Sublimation on microfiber adds a touch of magic, turning ordinary items into extraordinary works of art. So, embrace the potential, dive into the world of sublimation on microfiber, and let your imagination soar.

Frequently Asked Questions

Can you sublimate on 100% microfiber polyester?

Yes, you can! In fact, 100% microfiber polyester is one of the best options for sublimation printing. The high polyester content ensures superior ink absorption and color vibrancy, resulting in sharp and vivid designs.

Can you sublimate on a microfiber towel?

Absolutely! Sublimating on microfiber towels is a popular and rewarding application. Microfiber towels are excellent for custom designs, logos, and promotional purposes.

What temperature do you sublimate microfiber?

The sublimation temperature for microfiber can vary depending on the specific sublimation inks and the heat press being used. As a general guideline (what I use), the recommended sublimation temperature for microfiber is usually between 375°F to 400°F.

What Makes Microfiber Suitable for Sublimation?

Microfiber’s unique composition, typically a blend of polyester and polyamide, makes it an ideal substrate for sublimation printing. The fabric’s tightly woven structure allows for excellent ink absorption, ensuring deep and vivid colors.

Additionally, microfiber’s softness, absorbency, and quick-drying properties make it a versatile canvas for sublimation.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023