I’ve been using both DTF and sublimation in textile printing for a few years now. And I know how crucial it is to choose the right printing method for durable and visually striking designs. Here, I’ll guide you through my experience with DTF vs. sublimation printing including their advantages and disadvantages.

In a nutshell, DTF printing is great for printing on natural and dark fabrics, as it can produce bright and vibrant colors. Sublimation, on the other hand, is great for printing on light-colored polyester fabrics and on a wider variety of materials, including ceramics, metals, glass, wood, and plastics, etc.

So, which printing method is better? Let’s get into details and find the right technique for your needs.

Also, read about sublimation vs. screen printing.

Contents

Understanding DTF Printing

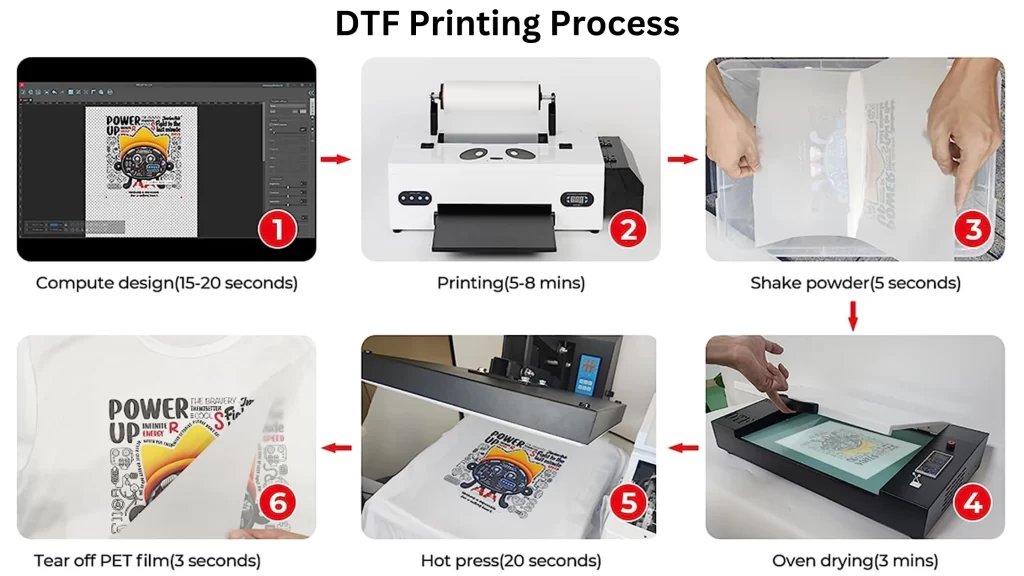

DTF (Direct-to-Film) printing is a relatively new printing method that uses a special type of ink and film to transfer designs onto fabric. The ink is printed onto the film in reverse, so that the design appears correctly when it is transferred to the fabric.

The film is then applied to the fabric and heat-pressed, which melts the ink and bonds it to the fabric.

DTF prints can be denser and have a slightly raised texture compared to sublimation prints.

Supplies Required for DTF Printing

The supplies required for DTF printing include:

- DTF Printer

- DTF Ink

- PET Film

- Adhesive powder

- Curing Oven

- Heat Press

- Protective Paper

Advantages of DTF Printing

- DTF printing allows vibrant colors to be transferred onto the fabric with exceptional clarity and precision. This results in eye-catching prints that showcase even the finest details.

- It works well with a wide range of fabrics, including cotton, polyester, blends, nylon, canvas, and even some synthetic materials. This versatility enables you to explore different options and create customized prints on diverse surfaces.

- DTF printing equipment is relatively affordable, making it a cost-effective option for small businesses and hobbyists.

Read instructions to sublimate on nylon.

Disadvantages of DTF Printing

- DTF printing is better suited for relatively simple designs rather than those with intricate patterns or fine gradients. Due to the nature of the film transfer, complex designs may not reproduce with the same level of accuracy and detail as simpler designs.

- Over time, DTF prints may experience some degree of cracking or peeling. This is because the ink is not bonded to the fabric as tightly as it is with sublimation printing. Factors such as the quality of the ink, film, and fabric, as well as the washing and care instructions followed, can influence the durability of the prints.

Durability Factors for DTF Printing

I’ve noticed that the quality of ink and film used in DTF printing plays a crucial role in the longevity of the print. Investing in high-quality materials ensures better adhesion and resistance to wear.

The fabric type and quality also influence the durability of DTF prints. Different fabrics have varying characteristics, and selecting the right fabric that complements the printing method can significantly impact the longevity of the print.

Additionally, do not forget the impact of washing. Always use gentle detergents and cold water to wash your DTF printing garments, and avoid excessive heat during drying.

Video Tutorial on DTF Printing

Exploring Sublimation Printing

Sublimation printing is an impressive technique that I’ve found to be fascinating, especially in textile printing.

It involves using heat to transfer sublimation ink onto a specially coated paper, which then fuses with the material’s surface, such as fabric, ceramic, metal, and acrylic.

Read a detailed guide on what is sublimation printing and how it works on different substrates.

Supplies Required for Sublimation Printing

The supplies required for sublimation printing include:

- Sublimation Printer

- Sublimation Ink

- Sublimation Paper

- Heat Press

- Sublimation Blanks (e.g., mugs, t-shirts, mousepads)

- Heat-resistant Tape

- Protective Paper

Advantages of Sublimation Printing

- Sublimation ink is very vibrant and can last for many years without fading. This makes it a great option for printing colorful and long-lasting images.

- This printing method can be used to print complex designs with fine details, making it a preferred choice for items like sportswear and home decor.

- Sublimation is possible on a wide variety of substrates, including fabric, ceramic, metal, wood, and acrylic, etc.

Here’s a guide on how to sublimate on acrylic.

Disadvantages of Sublimation Printing

- Sublimation ink can only be bonded to synthetic materials, such as polyester and nylon. This means that it cannot be used to print on natural materials, such as cotton or wool.

- The upfront cost of sublimation printing equipment is higher than some other printing methods. However, the cost of printing per item is typically lower, so the overall cost can be comparable.

Durability Factors for Sublimation Printing

To ensure the longevity of sublimation prints, several factors come into play. The quality of the sublimation ink and paper used is crucial. Investing in high-quality ink and compatible paper ensures better color retention and longevity.

Additionally, the composition and quality of the substrate being printed on, impact the durability of the prints. It is recommended to select materials that are specifically designed for sublimation printing. Polyester fabrics tend to yield the best results in terms of color vibrancy and durability.

Proper heat pressing and timing during the printing process are also essential. I have experienced that the 380°F to 400°F temperature and 50 to 60 seconds pressure time is perfect for best results.

DTF vs. Sublimation: Key Differences

The critical difference between DTF and sublimation printing lies in the transfer process. While DTF printing directly transfers the ink onto the fabric, sublimation printing involves the ink turning into a gas and then bonding with the surface of the material. This fundamental distinction leads to variations in the final results and the durability of the prints.

As an expert in the field of textile printing, I have had the opportunity to compare and contrast DTF and sublimation printing methods. I can shed light on their distinguishing factors, let’s dive into the key differences between the two:

Also, read the comparison between DTG vs Sublimation printing.

a. Print Size

When it comes to print size, DTF printing is typically limited to smaller print sizes, as the film used in the process is typically 12″ x 15″.

On the other hand, sublimation printing can handle larger print sizes efficiently. F570 sublimation printer can print up to 24″ wide, quite a width though.

b. Transfer Process & Print Quality

DTF printing involves transferring ink directly onto a film, which is then transferred onto the fabric or material. This process results in excellent print quality with sharp details and vibrant colors.

Sublimation printing, on the other hand, uses heat to transform ink into a gas, which then permeates the surface of the material. This technique provides consistent and fade-resistant prints, especially on synthetic materials.

As much as I love sublimation, I still prefer DTF for sharp and vibrant prints as long as it is related to garment printing.

c. Print Texture

DTF prints offer a slightly raised texture due to the ink being directly transferred onto the fabric. This texture adds a unique tactile element to the print. This texture can enhance the overall look and feel of the printed product.

In contrast, dye sublimation prints have a smooth texture as the ink becomes part of the material itself, creating a seamless and flat finish.

d. Suitable Materials

DTF printing offers more versatility when it comes to material compatibility. This printing method is compatible with various fabrics and materials, including cotton, polyester, and blends. It offers versatility in terms of substrate selection. This flexibility allows for printing on multiple textiles, accommodating different customer preferences.

Sublimation printing, however, is specifically suited for synthetic materials such as polyester or polymer-coated surfaces. Natural fabrics like cotton are not suitable for sublimation printing due to the ink’s requirement for a polymer coating.

e. Quantity of Products Required

DTF printing is well-suited for small to medium-scale production runs, and for smaller print runs or on-demand production. It allows for the creation of custom designs with minimal setup time. This makes it ideal for personalized items or smaller quantities.

Sublimation printing, on the other hand, is more efficient for larger production quantities. It enables mass production of the same design, making it suitable for businesses that require bulk orders.

f. Colors

Both DTF and sublimation printing methods offer a wide range of colors. However, dye sublimation printing tends to excel in color vibrancy and the ability to reproduce intricate color gradients and shades.

DTF printing also produces vibrant colors but may not achieve the same level of color saturation and complexity as sublimation prints, particularly in challenging color gradients.

However, DTF is one step ahead when it comes to printing neon colors on fabric, it’s not possible with sublimation printing.

g. Cost

A sublimation printer can range from around $300 for entry-level models to $800 or more for professional-grade printers with advanced features. The price of sublimation ink cartridges ranges from $50 to $150, and individual cartridges are priced between $10 and $30 each.

Sublimation paper typically comes in packs of 100 sheets, with costs ranging from $15 for basic-quality paper to $50 for premium-grade paper.

On the other hand, the DTF printer itself can range from around $2,000 for entry-level models to $5,000 or more for professional-grade printers with advanced features. DTF ink is typically sold in sets, ranging from $100 to $300 depending on the brand and quantity. DTF film, which is an essential component, is usually priced at around $1 to $3 per square foot.

A heat press machine, an essential investment for both DTF and sublimation printing, can range from $300 for smaller, basic models to over $1,000 for larger, commercial-grade machines.

Can You Use Sublimation Ink on DTF Film?

No, you cannot use sublimation ink on DTF film. Sublimation ink is designed to be vaporized and bonded to a substrate using heat and pressure. DTF film, on the other hand, is designed to be used with a special type of ink that is applied to the PET film in reverse and then heat-pressed onto the fabric.

If you try to use sublimation ink on DTF film, the ink will not vaporize and will not bond to the film. This will result in a blurry and uneven print.

I have personally tried to use sublimation ink on DTF film, and I can confirm that it does not work. The ink just sits on top of the film and does not bond to it.

Final Words: Which is Better?

So, the choice between DTF and sublimation printing comes down to understanding their differences and aligning them with your specific goals.

Both methods have their strengths, with DTF offering versatility in bold colors and a wide range of materials, while sublimation excels in vibrant colors and mass production efficiency.

However, it’s crucial to prioritize durability, considering factors like ink quality, fabric type, curing techniques, and care instructions. By making informed decisions based on your specific needs and embracing emerging technologies, you can achieve exceptional results in the world of textile printing.

Frequently Asked Questions

Does sublimation or DTF last longer?

Both sublimation and DTF prints can be durable, but the longevity depends on factors such as ink quality, material type, and proper care. Sublimation prints tend to have excellent color retention, while DTF prints may be prone to cracking or peeling over time if not properly cared for.

Can you sublimate on DTF?

No, sublimation cannot be directly applied to DTF prints. Sublimation requires a specialized coating on the material to work effectively, whereas DTF printing involves a different transfer process.

Is DTF better than screen printing?

The choice between DTF and screen printing depends on specific requirements. DTF printing offers high detail and vibrant colors but may have limitations for complex designs. Screen printing, on the other hand, allows for a wider range of materials and can be cost-effective for large production runs.

Which method, DTF or Sublimation, is better for printing on cotton fabrics?

DTF is better for printing on cotton fabrics. However, on the other hand, sublimation printing is not suitable for cotton as it requires synthetic materials like polyester to achieve optimal results.

- 5 Best 13×19 Sublimation Printer for Wide Format Substrates - December 27, 2023

- Best 11×17 Sublimation Printer to Print Tabloid Size Paper - December 26, 2023

- Epson ET-8550 vs ET-15000: Best Wide-Format EcoTank Printer - December 25, 2023

![How to Sublimate on Wood? Pro Tips & Best Method [Tested] wood sublimation](https://subliprinting.com/wp-content/uploads/2022/04/wood-sublimation-150x150.png)